Introduction

Pipe clamps are essential tools in many industries, from plumbing to woodworking. They play a key role in securing pipes, ensuring stability, and enabling smooth system function. Whether you’re working with plumbing, gas lines, or wood, knowing how to use pipe clamps effectively is crucial.

In this guide, we will cover different types of pipe clamps, how they work, and how to use them efficiently for various applications. By the end, you'll be equipped with the knowledge to select and install the right pipe clamps for your project.

What Are Pipe Clamps?

Definition and Purpose

A pipe clamp is a mechanical device used to secure and support pipes, preventing unwanted movement while allowing for thermal expansion or contraction. Pipe clamps are most commonly used in systems that require pipes to be mounted or suspended safely, such as in plumbing, HVAC, and industrial settings. They are designed to keep pipes in place, avoiding vibrations or damage caused by movements.

The primary function of a pipe clamp is to maintain the pipe’s position while allowing for the natural movement that can occur due to temperature changes, pressure variations, or mechanical stress. In plumbing, for instance, the right pipe clamp can ensure that the system remains operational even under varying environmental conditions.

Types of Pipe Clamps

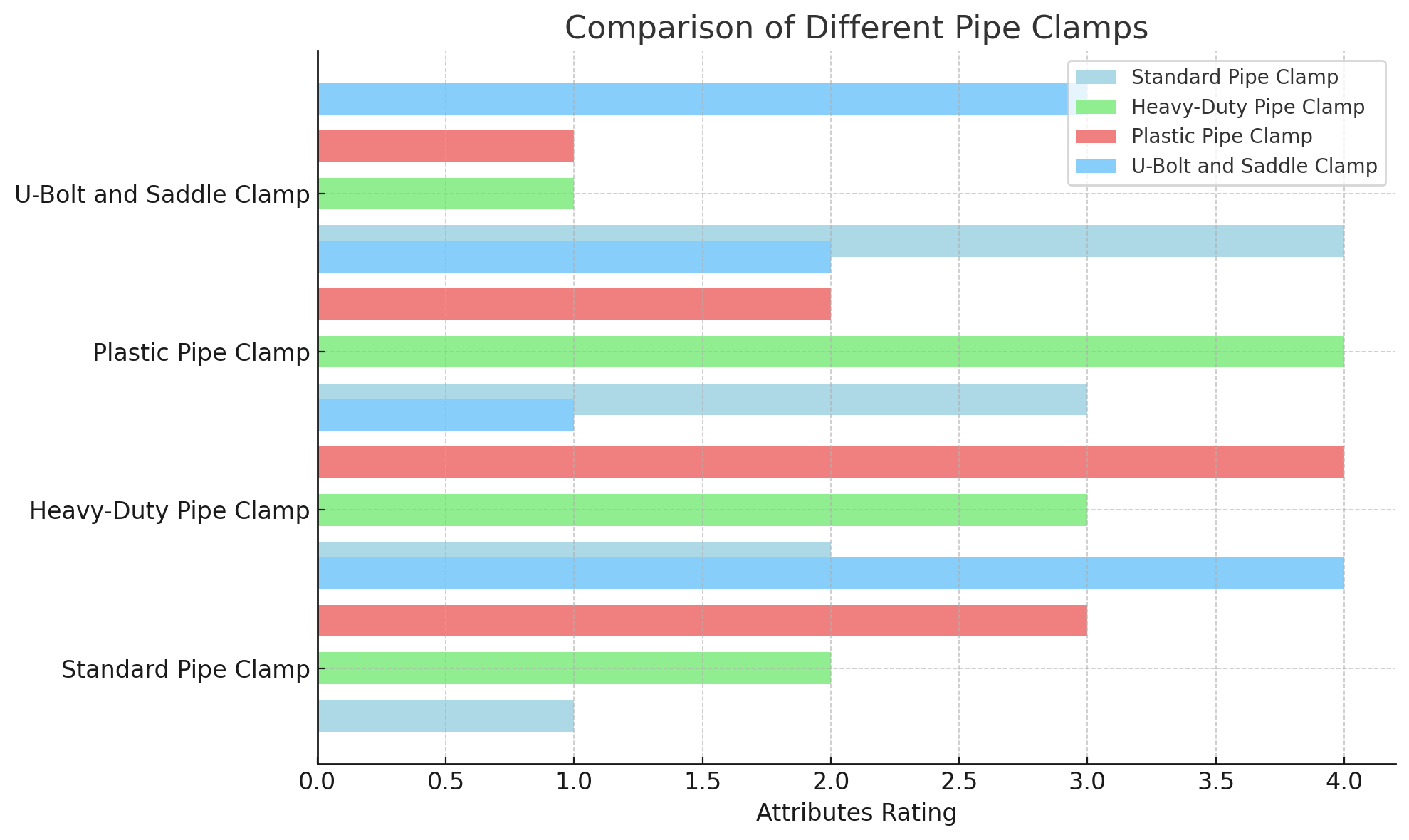

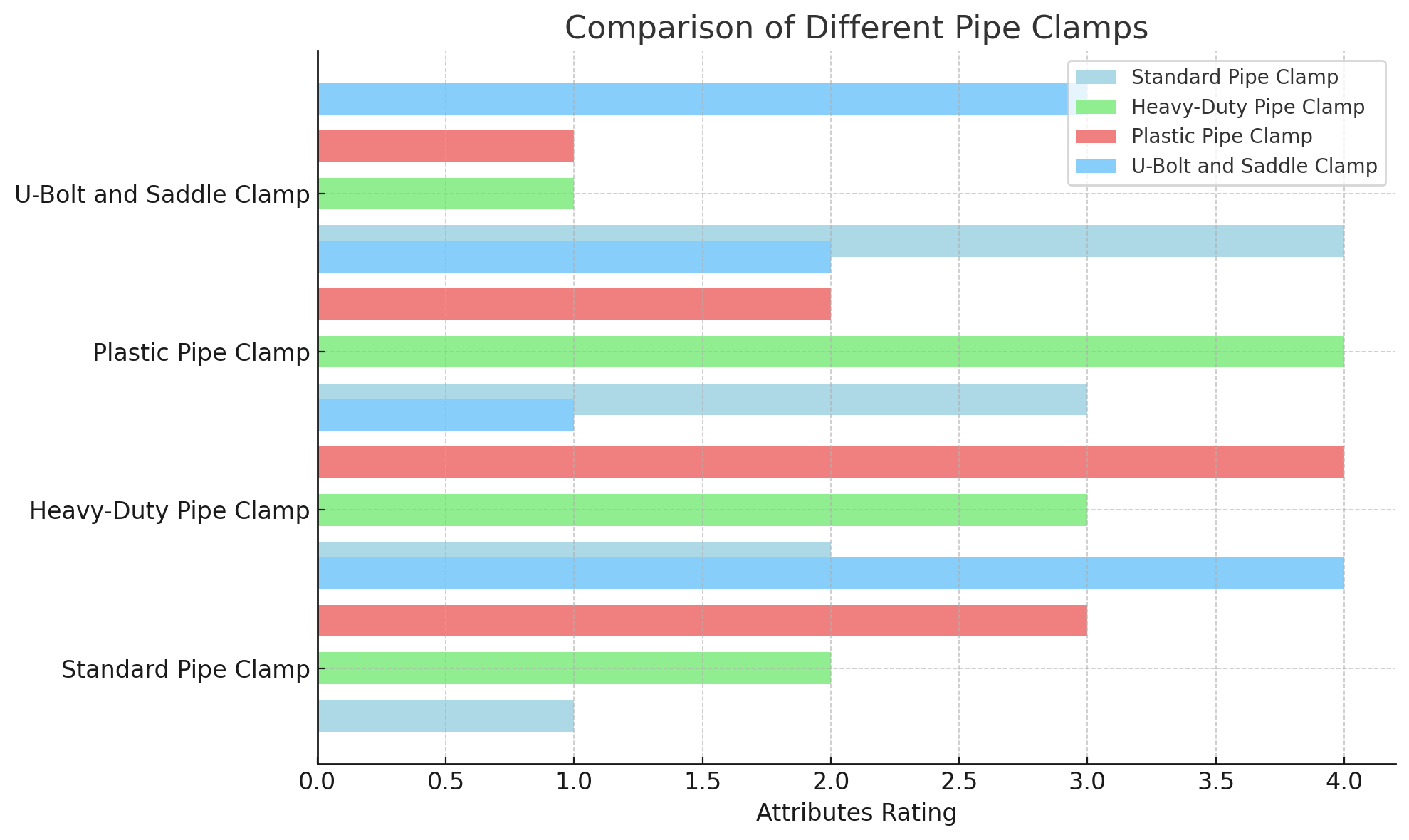

There are several types of pipe clamps, each suited for different applications. Here are the most common:

● Standard Pipe Clamps: These clamps are generally used for basic pipe support. They come with adjustable options, making them versatile and suitable for various pipe sizes. They are commonly used in plumbing and heating systems where temperature changes and minimal movement are expected.

● Heavy-Duty Pipe Clamps: Built for more substantial applications, heavy-duty pipe clamps are designed to bear significant loads. These are ideal for use in industrial settings or where pipes need to support high pressure or weight.

● Plastic Pipe Clamps: These are commonly used for lightweight, smaller pipes, especially plastic or copper pipes. They are perfect for domestic plumbing or other low-stress installations.

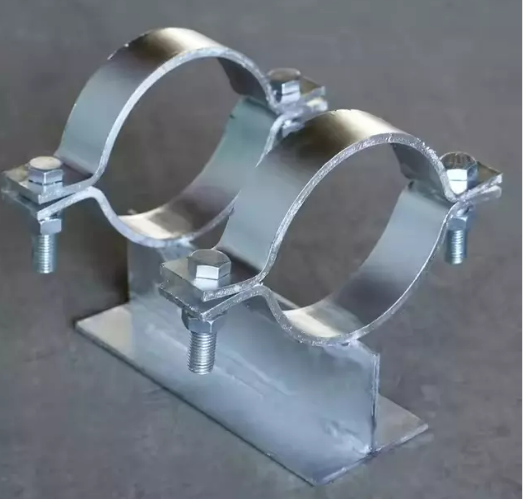

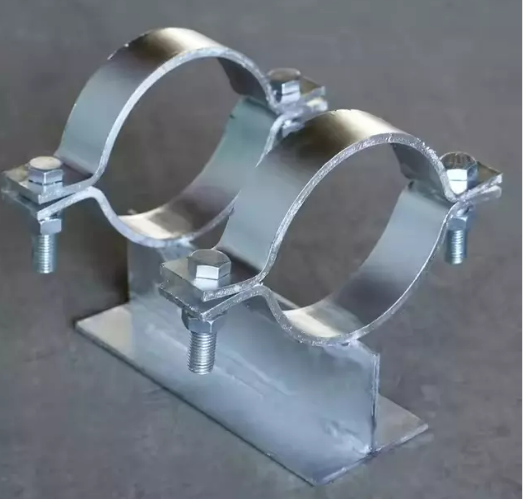

● U-Bolts and Saddle Clamps: These are traditional pipe supports typically used to hold steel or copper pipes. They provide a simple solution for securing larger pipes in place, often found in industrial environments where no special insulation or vibration dampening is required.

Type of Pipe Clamp | Material | Best For | Advantages |

Standard Pipe Clamp | Steel, Stainless | Basic plumbing, heating systems | Adjustable, versatile for various pipe sizes |

Heavy-Duty Pipe Clamp | Steel, Galvanized | Industrial applications, high-load pipes | High load-bearing capacity, durable |

Plastic Pipe Clamp | Plastic, PVC | Plastic, copper pipes, light-duty systems | Corrosion-resistant, lightweight |

U-Bolt and Saddle Clamp | Steel, Stainless | Steel, copper pipes | Simple, cost-effective for larger pipes |

How Do Pipe Clamps Work?

Basic Mechanism of Pipe Clamps

Pipe clamps work by wrapping around pipes and securing them to a surface, such as a wall, ceiling, or structural frame. The clamp is designed to keep the pipe fixed in place while allowing slight movement due to thermal expansion or contraction. There are several designs for how clamps secure pipes, including sliding clamps and bolted ones.

For most pipe clamps, the mechanism involves tightening screws or bolts that keep the two halves of the clamp together, holding the pipe tightly in place. Some modern designs even include quick-locking mechanisms that allow for faster installation, making them ideal for large-scale installations or maintenance work.

Applications in Various Systems

● Suspended Pipes: In many applications, such as HVAC or plumbing, pipes are suspended from ceilings. Pipe clamps help ensure that pipes stay in place without touching walls or ceilings, which could cause damage due to friction. Suspended pipes are often secured using specialized pipe hangers or saddle clamps, providing adequate support without compromising the integrity of the installation.

● Thermal Expansion: Pipe clamps also allow for thermal expansion. Pipes expand and contract when exposed to temperature changes, and a proper pipe clamp will ensure that the pipe can shift slightly without becoming stressed or damaged. This is particularly important in plumbing and heating systems, where hot water can cause pipes to expand, and cold temperatures may cause them to contract.

Step-by-Step Guide: How to Use Pipe Clamps Effectively

Preparing the Pipe and Surface

Before using pipe clamps, it's important to prepare both the pipe and the surface where the clamp will be installed.

● Choose the Right Size: Pipe clamps come in various sizes, so it is essential to measure the outer diameter of the pipe to ensure you select the right clamp. Using a clamp that is too large or small could result in a poor fit, leading to instability or pipe damage.

● Surface Preparation: Clean the surface where the pipe clamp will be attached to remove any rust, dirt, or debris. This will help ensure a secure attachment and prevent rust from forming on both the pipe and clamp. Additionally, ensure that the surface is flat and free from sharp edges that could damage the pipe.

Installation Process

Follow these steps to install a pipe clamp effectively:

1. Position the Pipe: Ensure that the pipe is aligned correctly in the desired position. This may involve ensuring it is level or angled according to the needs of the project.

2. Place the Clamp Around the Pipe: Open the pipe clamp and place it around the pipe. Some clamps, like saddle clamps, will sit over the top half of the pipe, while others will completely encircle it. Be sure to align the clamp’s holes with the corresponding mounting surface.

3. Tighten the Screws or Bolts: Once the clamp is in place, tighten the screws or bolts securely. However, avoid overtightening, as this could lead to damage to both the clamp and the pipe. A snug fit is sufficient to keep the pipe stable while allowing for the necessary flexibility.

4. Check for Flexibility: Ensure that the clamp doesn’t completely restrict movement. The pipe should be able to expand or contract slightly without causing strain on the system.

Step | Action |

1. Prepare the Pipe | Measure the outer diameter to ensure proper clamp size. |

2. Position the Pipe | Align the pipe in the correct position (level or angled). |

3. Attach the Clamp | Place the clamp around the pipe and secure it with screws. |

4. Tighten the Screws | Tighten screws or bolts firmly but not excessively. |

5. Check for Flexibility | Ensure the clamp allows slight movement for thermal expansion. |

Key Tips for Successful Pipe Clamp Installation

● Avoid Over-tightening: Tightening too much can cause damage to the pipe and clamp. Always check that the clamp is firm but not overly tight.

● Use Proper Spacing: Space the clamps properly to distribute the load evenly along the length of the pipe. This helps avoid excess strain on any one section of the pipe.

● Check for Vibration: For systems exposed to vibrations, such as heating or industrial applications, use rubber linings or vibration isolators to reduce noise and wear on the pipe.

Choosing the Right Pipe Clamp for Your Project

Factors to Consider

When selecting a pipe clamp for your project, it’s important to consider the following:

● Pipe Material: Different pipe materials require different types of clamps. For metal pipes, a traditional metal clamp may be suitable. For plastic pipes, plastic or rubber-lined clamps are recommended to prevent damage and ensure a secure fit.

● Environmental Conditions: If your pipes will be exposed to corrosive environments, choose clamps that are made from corrosion-resistant materials like stainless steel. Coated or galvanized clamps are also good options for outdoor installations where weathering could be an issue.

● Pipe Size: The size of the pipe directly impacts the clamp selection. Ensure that the clamp fits the pipe’s outer diameter to prevent leaks or instability in the system.

Best Applications for Different Clamps

● Standard Pipe Clamps: These are best used for general plumbing and heating systems where the pipe does not experience heavy load or extreme conditions.

● Heavy-Duty Clamps: These clamps are designed for industrial settings where large pipes carry high-pressure liquids or gases. They provide superior load-bearing capacity and are ideal for systems that face heavy usage.

● Plastic Clamps: Plastic clamps are perfect for domestic applications, particularly when working with smaller, lightweight pipes or in systems where corrosion is a concern.

Type of Pipe Clamp | Cost Range | Best For | Long-Term Value |

Standard Pipe Clamp | Low to Medium | Basic plumbing, residential setups | Affordable, good for regular installations |

Heavy-Duty Pipe Clamp | Medium to High | Industrial and commercial systems | High durability, cost-effective for large projects |

Plastic Pipe Clamp | Low | Lightweight or plastic pipes | Economical and corrosion-resistant for domestic use |

Common Pipe Clamp Issues and How to Avoid Them

Over-tightening and Pipe Damage

One of the most common mistakes when using pipe clamps is over-tightening, which can lead to pipe deformation or clamp failure. Always ensure that the clamp is securely tightened without excessive force.

Misalignment of Pipes

Improper alignment can place unnecessary stress on the pipe, leading to leaks or failures over time. Make sure that the pipe is aligned properly and that clamps are evenly spaced to avoid misalignment.

Corrosion and Wear

In environments where pipes are exposed to moisture or chemicals, corrosion can be a significant concern. Ensure that the clamps used are resistant to corrosion, and consider adding rubber linings for additional protection.

Tip: Use corrosion-resistant clamps for outdoor installations or in wet environments to ensure long-lasting performance.

Issue | Cause | Solution |

Loose Clamps | Screws/bolts have loosened over time | Tighten the screws or bolts to secure the clamp. |

Pipe Slipping | Incorrect clamp size or loose installation | Use additional rubber or plastic padding to prevent slipping. |

Corrosion | Exposure to moisture or corrosive materials | Use corrosion-resistant clamps or apply a protective coating. |

How to Maintain and Troubleshoot Pipe Clamps

Regular Inspection and Maintenance

Pipe clamps require regular inspection to ensure they remain in good condition. Look for signs of wear, such as rust, corrosion, or loose bolts.

● Check for Rust or Wear: Inspect the clamps regularly for signs of rust, especially if they are exposed to outdoor or wet conditions.

● Ensure Tightness: Over time, the screws or bolts in the clamps may loosen. Regularly check and tighten them to maintain a secure fit.

Troubleshooting Common Problems

● Loose Clamps: If you notice that a clamp has become loose, simply tighten the screws or bolts. If the clamp still doesn’t hold the pipe securely, consider replacing it.

● Pipe Slipping: If the pipe is slipping within the clamp, try adding extra padding or using a rubber lining to create more friction.

Conclusion

Pipe clamps are essential for maintaining safe and efficient piping systems. By understanding the various types, selecting the right one, and following proper installation and maintenance steps, you can ensure long-lasting reliability. Regular inspection and troubleshooting prevent common issues. Whether in plumbing, industrial gas lines, or woodworking, mastering pipe clamp usage is invaluable.

At WEIHENG, we offer high-quality pipe clamps designed for durability and ease of installation, providing unmatched value for all your piping needs.

FAQ

Q: What is a Pipe Clamp used for?

A: A Pipe Clamp is used to secure pipes in place, preventing movement while allowing for thermal expansion or contraction. It's essential in plumbing, HVAC, and industrial systems to ensure pipes remain stable and functional.

Q: How do I install a Pipe Clamp correctly?

A: To install a Pipe Clamp, first position the pipe where it needs to go, then place the clamp around the pipe. Tighten the screws or bolts securely, but avoid over-tightening. Ensure there’s slight flexibility for expansion.

Q: Why is it important to use a Pipe Clamp in plumbing?

A: A Pipe Clamp ensures pipes are properly secured, preventing damage or leaks caused by movement or thermal expansion. It also maintains the integrity of the plumbing system, especially in high-pressure environments.

Q: Can I use a Pipe Clamp for both metal and plastic pipes?

A: Yes, Pipe Clamps come in different materials. Use metal clamps for metal pipes and plastic clamps for plastic pipes to ensure proper fit and avoid corrosion or damage.

Q: What are the advantages of using a Pipe Clamp?

A: A Pipe Clamp provides stability and flexibility, securing pipes while allowing for expansion. It helps prevent damage from vibrations, ensuring long-lasting, reliable pipe installations.