Introduction

In plumbing, electrical, or HVAC systems, securing pipes is essential for performance and longevity. Pipe clips and pipe clamps are both used for this purpose, but they differ in design, function, and strength. Understanding these differences can help you choose the right tool for your project.

In this article, we will explore the key distinctions between pipe clips and pipe clamps, their applications, and how to decide which is best for your needs.

What Are Pipe Clips?

Definition and General Features

A pipe clip is a simple, lightweight device designed to hold pipes securely in place. Typically, it consists of a U-shaped or circular bracket that partially surrounds the pipe, allowing it to be mounted onto a wall, ceiling, or floor. The main function of a pipe clip is to stabilize and support the pipe without applying excessive pressure. These clips are often secured using screws or bolts, and some versions include a rubber or plastic lining to cushion the pipe, reducing vibration and preventing damage.

Pipe clips are available in various sizes and materials to accommodate different pipe diameters and environments. Common materials used for pipe clips include plastic, steel, and rubber, which offer varying degrees of durability and flexibility.

Applications of Pipe Clips

Pipe clips are commonly used in applications where pipes do not need to withstand high pressure or heavy loads. Some of the most common uses for pipe clips include:

● Residential plumbing: Pipe clips are ideal for supporting water and gas lines in residential systems where heavy clamping force is unnecessary.

● HVAC systems: In heating, ventilation, and air conditioning installations, pipe clips keep ducting and piping secure while preventing unnecessary movement.

● Electrical conduit systems: Pipe clips are often used to secure electrical conduits, ensuring that cables remain in place and do not vibrate or shift.

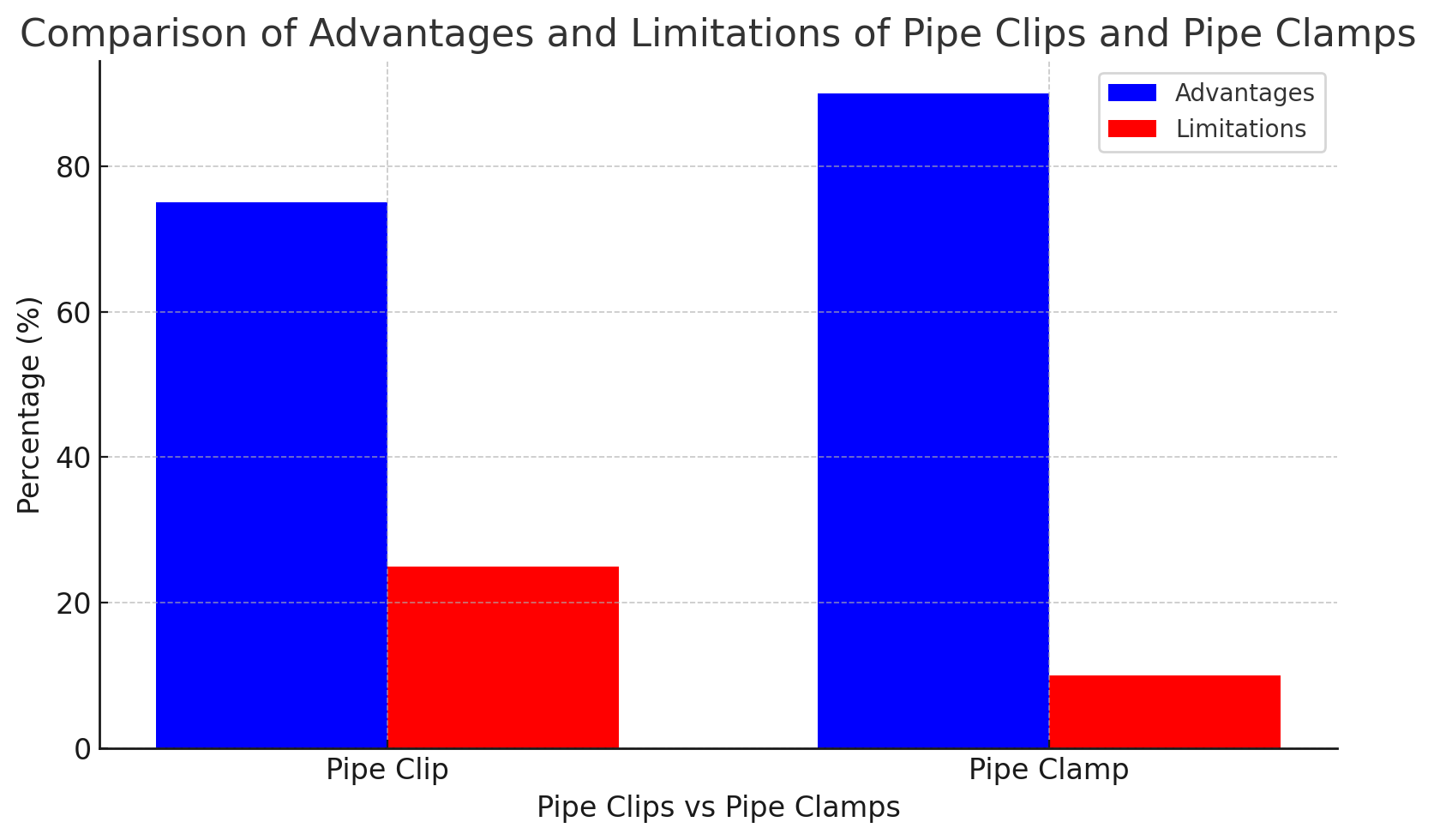

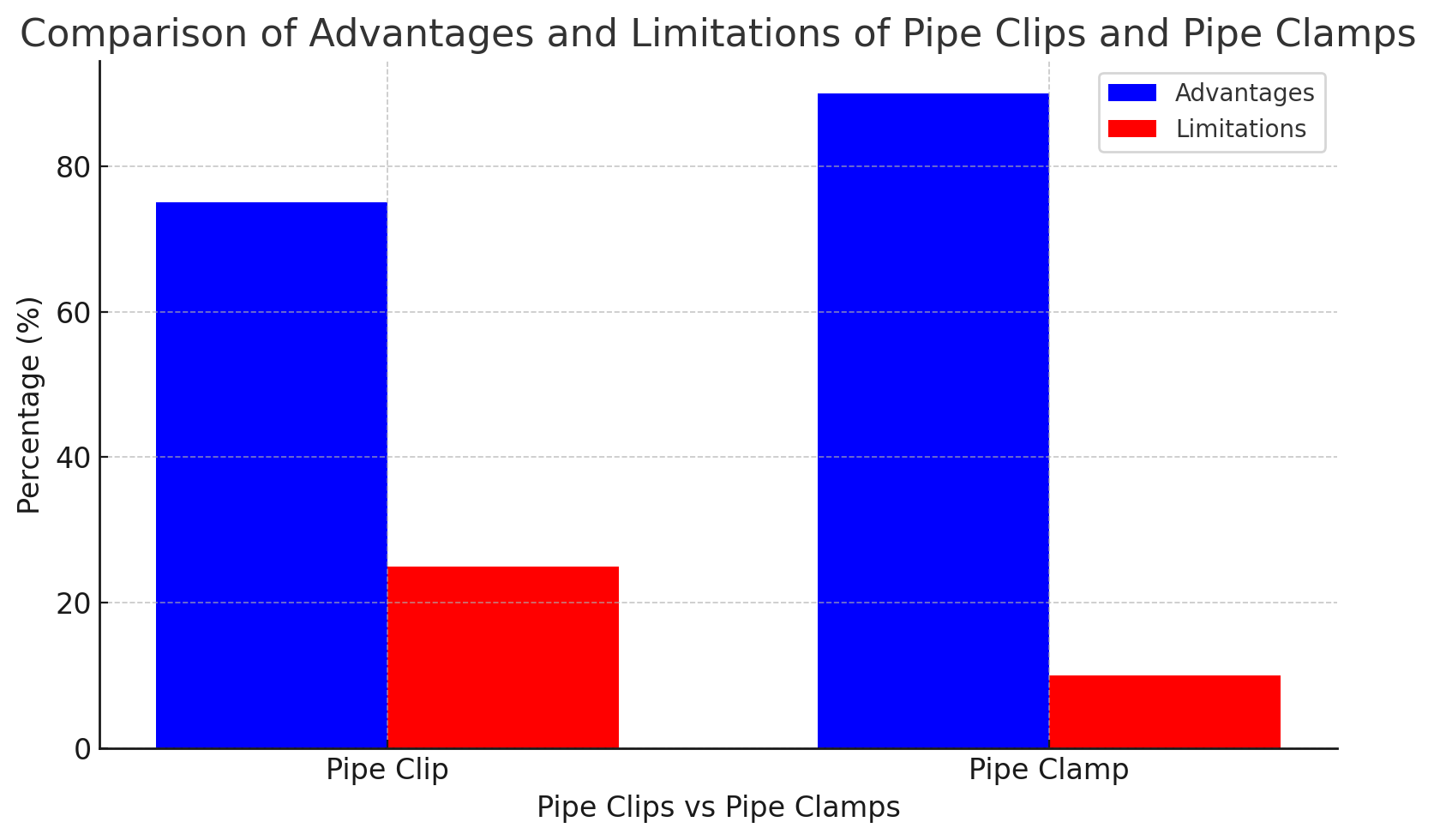

Advantages and Limitations of Pipe Clips

Advantages:

● Cost-effective: Pipe clips are generally less expensive than pipe clamps, making them an ideal choice for budget-conscious projects.

● Ease of installation: With simple designs and minimal hardware, pipe clips are easy to install and do not require specialized tools.

● Noise reduction: The rubber or plastic linings commonly found in pipe clips help absorb vibrations, reducing noise.

Limitations:

● Limited load capacity: Pipe clips are not designed to support heavy loads or withstand high-pressure environments.

● Lack of sealing capability: Unlike pipe clamps, pipe clips cannot create a seal between pipe sections, making them unsuitable for applications requiring leak-proof connections.

What Are Pipe Clamps?

Definition and General Features

A pipe clamp is a more robust and versatile solution designed to securely hold pipes under demanding conditions. Typically made from a band or strap that encircles the pipe, a pipe clamp uses screws, bolts, or a tightening mechanism to apply pressure and securely hold the pipe in place. Unlike pipe clips, pipe clamps can fully encircle the pipe, providing a much stronger hold. Many pipe clamps also feature gaskets or sealing materials, allowing them to create leak-proof connections.

Pipe clamps are usually made from more durable materials such as stainless steel, galvanized steel, or carbon steel to ensure long-lasting performance, even in harsh environments.

Applications of Pipe Clamps

Pipe clamps are essential in applications where pipes are exposed to high pressure, heavy loads, or extreme conditions. Some common applications include:

● Industrial piping: Pipe clamps are crucial in industrial setups where pipes are under significant stress and need to be tightly secured.

● Automotive exhaust systems: Pipe clamps are used in automotive systems to ensure exhaust pipes are securely fastened and sealed.

● High-pressure plumbing: In systems where pipes are exposed to high pressure, such as water treatment plants or hydraulic systems, pipe clamps ensure a secure and leak-proof connection.

Advantages and Limitations of Pipe Clamps

Advantages:

● Stronger hold: Pipe clamps provide a much stronger grip than pipe clips, making them suitable for high-pressure or heavy-duty applications.

● Sealing capability: Some pipe clamps include rubber linings or gaskets, which allow them to create leak-proof seals between pipe sections.

● Durability: Pipe clamps are typically made from corrosion-resistant materials, making them ideal for use in harsh environments or high-temperature conditions.

Limitations:

● Higher cost: Pipe clamps are generally more expensive than pipe clips, primarily due to their more robust design and materials.

● More complicated installation: The installation of pipe clamps often requires tools and more time due to their tightening mechanisms.

Key Differences Between Pipe Clips and Pipe Clamps

Design and Structure

The primary difference between pipe clips and pipe clamps lies in their design. While pipe clips are simple U-shaped or circular brackets that provide partial support to the pipe, pipe clamps fully encircle the pipe, offering a more secure and stable hold. Pipe clamps are often equipped with tightening mechanisms such as bolts or screws, which allow them to apply pressure and ensure a tight grip on the pipe.

Functionality and Load Capacity

Pipe clips are best suited for lightweight applications where pipes need basic support and stability. They are not designed to handle high loads or withstand significant pressure. In contrast, pipe clamps are built for heavy-duty applications, offering higher load capacity and better performance under pressure. Pipe clamps can also provide sealing capabilities, making them ideal for applications where a leak-proof connection is essential.

Installation and Adjustability

Pipe clips are easy to install and require minimal tools. They are typically screwed into place and are adjustable to fit different pipe sizes. On the other hand, pipe clamps often require more time and effort to install. The installation process involves tightening bolts or screws to apply pressure, and pipe clamps are usually adjustable to accommodate varying pipe diameters. Pipe clamps also tend to require additional mounting hardware such as brackets, depending on the application.

Feature | Pipe Clip | Pipe Clamp |

Primary Function | Support and stabilize pipes | Secure, connect, or seal pipes |

Design | U-shaped or circular bracket | Band or strap with tightening mechanism |

Strength | Light support | High clamping force and durability |

Applications | Plumbing, HVAC, electrical conduit | Industrial, automotive, high-pressure plumbing |

Sealing Capability | No sealing capability | Often includes sealing gaskets |

Ease of Installation | Easy and quick | Requires tightening for secure fit |

Cost | More affordable | Higher cost due to durability and functionality |

When to Use Pipe Clips and When to Use Pipe Clamps

Scenarios Best Suited for Pipe Clips

Pipe clips are an excellent choice for applications where pipes need steady support but are not subject to high pressure or heavy loads. Here are some scenarios where pipe clips are ideal:

● Residential plumbing: Use pipe clips for supporting water or gas lines where the pipes are lightweight and not exposed to high pressure.

● HVAC and electrical systems: In heating, ventilation, and air conditioning, as well as electrical conduit installations, pipe clips are perfect for holding pipes in place without requiring a strong grip.

● Light commercial installations: Pipe clips are often used in small commercial projects where minimal force is needed to secure pipes.

Scenarios Best Suited for Pipe Clamps

Pipe clamps are essential when dealing with heavy-duty applications or high-pressure systems. Here’s when you should choose pipe clamps:

● Industrial piping systems: Use pipe clamps in industrial environments where pipes are subjected to high pressure, vibration, or heavy loads.

● Automotive exhaust systems: Pipe clamps are critical in exhaust systems, ensuring a tight seal and secure fit to prevent leaks and withstand high temperatures.

● Plumbing systems under pressure: For water or gas pipelines that require leak-proof connections, pipe clamps provide the necessary strength and sealing capability.

Scenario | Pipe Clip | Pipe Clamp |

Light-duty applications | Ideal for light plumbing tasks, HVAC systems, electrical conduit systems | Not recommended |

High-pressure systems | Not suitable | Essential for sealing and secure fitting |

Heavy-duty industrial use | Not recommended | Best suited for heavy loads, high temperatures, and industrial setups |

Pipe movement control | Offers basic support, no movement allowance | Accommodates slight movement due to tight grip |

Material Considerations for Pipe Clips and Clamps

Common Materials for Pipe Clips

Pipe clips are made from a variety of materials, each chosen for its suitability in different environments:

● Plastic: Lightweight and corrosion-resistant, plastic pipe clips are ideal for indoor applications where pipes are not subjected to high stress or harsh conditions.

● Steel: Galvanized or stainless steel clips are used in more demanding applications, providing additional strength and resistance to corrosion.

● Rubber-lined metal: This combination provides the strength of metal while offering vibration dampening and noise reduction properties.

Common Materials for Pipe Clamps

Pipe clamps are made from materials that are designed to withstand extreme conditions:

● Stainless steel: Stainless steel clamps are highly durable and resistant to corrosion, making them ideal for outdoor, industrial, and marine environments.

● Galvanized steel: Galvanized clamps offer a more affordable solution compared to stainless steel, providing good durability and corrosion resistance.

● Carbon steel: Used in heavy-duty applications, carbon steel clamps are often coated or painted to resist rust and corrosion.

Material Type | Pipe Clip Application | Pipe Clamp Application |

Plastic | Lightweight, corrosion-resistant | Not ideal for heavy-duty tasks |

Metal (Steel) | For medium support, corrosion resistance | Common for heavy-duty and outdoor use |

Rubber-lined | For reducing noise and vibration | Used in both clips and clamps for vibration control |

Stainless Steel | Not commonly used | Ideal for high-pressure, corrosive environments |

Conclusion

In conclusion, pipe clips and pipe clamps both serve crucial roles in securing pipes, but they differ in purpose and application. Pipe clips are cost-effective and ideal for light-duty tasks, offering basic support. However, they lack the strength and sealing capability of pipe clamps. Pipe clamps, on the other hand, provide a stronger, leak-proof hold, making them suitable for heavy-duty and high-pressure environments.

When choosing between the two, consider factors like pipe size, load requirements, and environmental conditions. Selecting the right tool ensures long-term safety and durability for your piping system.

Final Thoughts: Whether you need basic support or heavy-duty security, choose the right device for your project. For more demanding installations, pipe clamps are the ideal choice, while pipe clips suffice for lighter tasks.

At WEIHENG, we offer high-quality pipe securing solutions designed to meet the needs of various applications. Choose our reliable products to ensure your piping systems are secure and durable for years to come.

FAQ

Q: What is the main difference between a pipe clip and a pipe clamp?

A: Pipe clips provide basic support and stability for pipes, while pipe clamps offer a stronger, more secure hold, often used for heavy-duty or high-pressure applications.

Q: Can I use a pipe clip for high-pressure systems?

A: No, pipe clips are not designed for high-pressure systems. For such applications, a pipe clamp would be a better choice due to its stronger grip and sealing capabilities.

Q: When should I use a pipe clamp instead of a pipe clip?

A: Use a pipe clamp for high-pressure, industrial, or heavy-duty applications where a leak-proof connection and secure hold are needed. Pipe clips are more suitable for lighter tasks.

Q: Are pipe clips or pipe clamps more cost-effective?

A: Pipe clips are generally more affordable than pipe clamps. However, pipe clamps offer superior performance in high-load and high-pressure environments, justifying the higher cost.

Q: How do pipe clamps handle pipe movement?

A: Pipe clamps can accommodate slight pipe movement due to their tight grip and ability to absorb pressure. Some pipe clamps also include gaskets for leak-proof sealing.

Q: Can I install a pipe clip myself, or do I need professional help?

A: Pipe clips are easy to install with basic tools. For more complex or heavy-duty applications, such as with pipe clamps, professional assistance may be needed.

Q: What materials are used in pipe clamps?

A: Pipe clamps are typically made from durable materials like stainless steel or galvanized steel, ensuring strength and resistance to corrosion, ideal for heavy-duty or outdoor use.