Introduction

Choosing the right pipe clamp is critical for ensuring a secure and durable piping system. With so many options available, it’s easy to make the wrong choice.

In this article, we will explore the key factors to consider when selecting a pipe clamp. You’ll learn how pipe material, size, and environmental conditions affect your decision-making process.

What Is a Pipe Clamp?

Definition and General Features

A pipe clamp is a mechanical device designed to secure and hold pipes in place. It is generally a U-shaped, circular, or semi-circular clamp that fits around a pipe, securing it to a wall, ceiling, or other surface. Pipe clamps are primarily used in plumbing, heating, drainage, and electrical work to provide support and prevent movement.

These clamps are commonly made from various materials like stainless steel, plastic, or galvanized steel. Some are lined with rubber or other materials to protect the pipe from abrasion or corrosion. The primary function of a pipe clamp is to hold the pipe securely while allowing for slight movements caused by temperature changes, vibrations, or system expansion.

Common Uses of Pipe Clamps

Pipe clamps are essential in a variety of settings. Here are a few common uses:

● Plumbing: Used to secure water pipes in residential, commercial, and industrial plumbing systems.

● HVAC: Secure ducts and tubing, preventing movement that could affect airflow and system efficiency.

● Electrical: Used to attach electrical conduit to surfaces, protecting wires from damage.

● Industrial: Employed in high-pressure, high-temperature environments to support pipes carrying chemicals, gas, and other industrial fluids.

Each application has unique demands that influence the type of clamp required, making it important to select a pipe clamp based on its intended use.

Pipe Clamp Materials

The material of a pipe clamp is crucial for its performance and longevity. The most common materials used for pipe clamps include:

● Stainless Steel: Offers excellent resistance to corrosion, making it ideal for high-humidity, outdoor, or chemical environments.

● Plastic: Lightweight and corrosion-resistant, plastic clamps are commonly used in plumbing and HVAC systems, especially in less demanding conditions.

● Galvanized Steel: Offers moderate corrosion resistance, often used for outdoor or less-critical applications.

● Rubber Lined: Rubber-lined clamps are used to protect delicate pipes, such as copper or PVC, from damage due to abrasion or vibration.

Each material has advantages depending on the environmental factors and the nature of the system in which it is being used.

Material | Best Used For | Features |

Stainless Steel | Outdoor, high-pressure systems, industrial use | Corrosion-resistant, durable, high strength |

Galvanized Steel | General plumbing, medium-duty applications | Affordable, rust-resistant in mild conditions |

Plastic (Nylon/PP) | Light-duty applications, indoors | Lightweight, resistant to corrosion, cost-effective |

Copper/Brass | Plumbing systems, residential use | Aesthetic, non-corrosive in water systems |

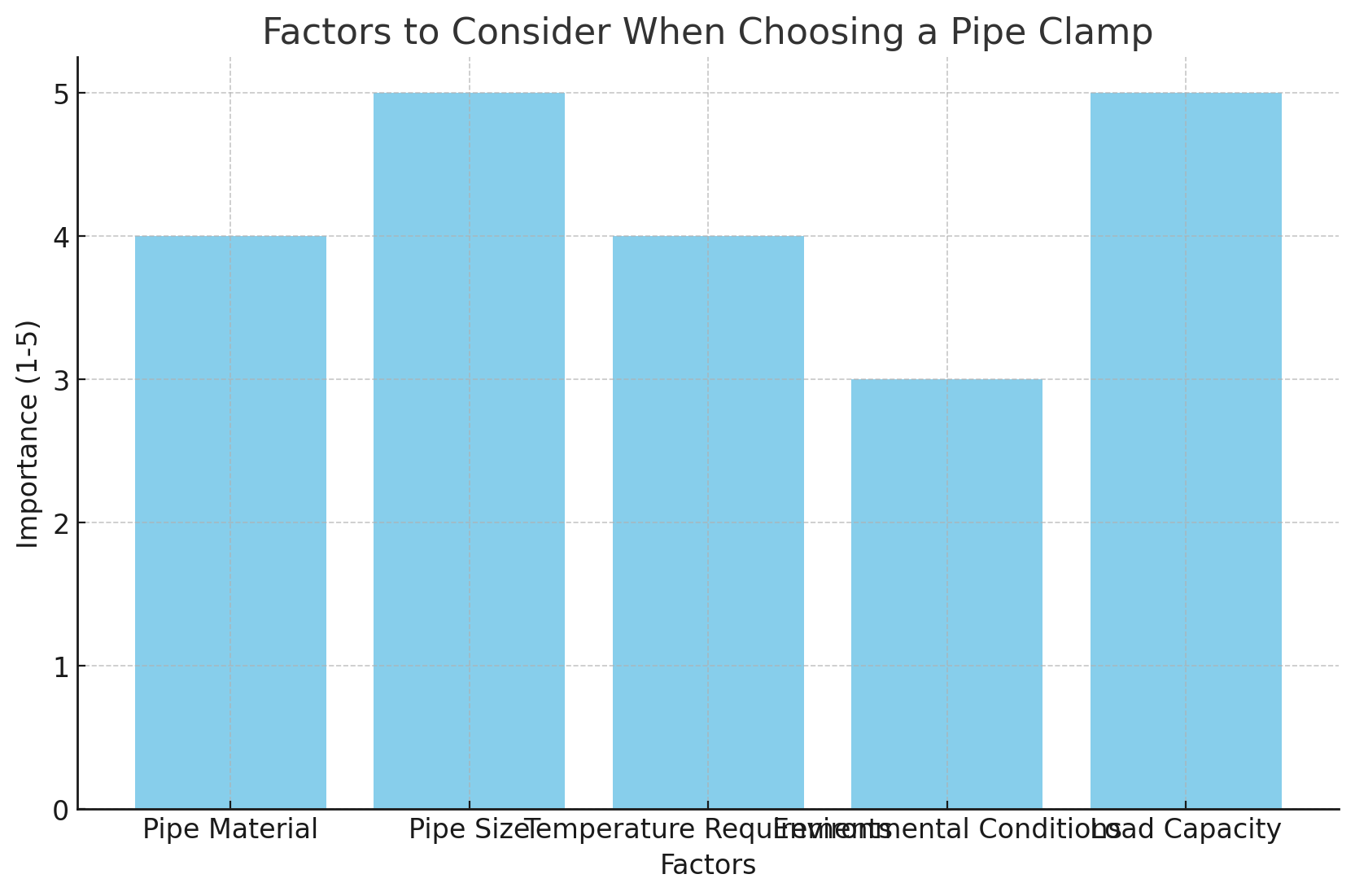

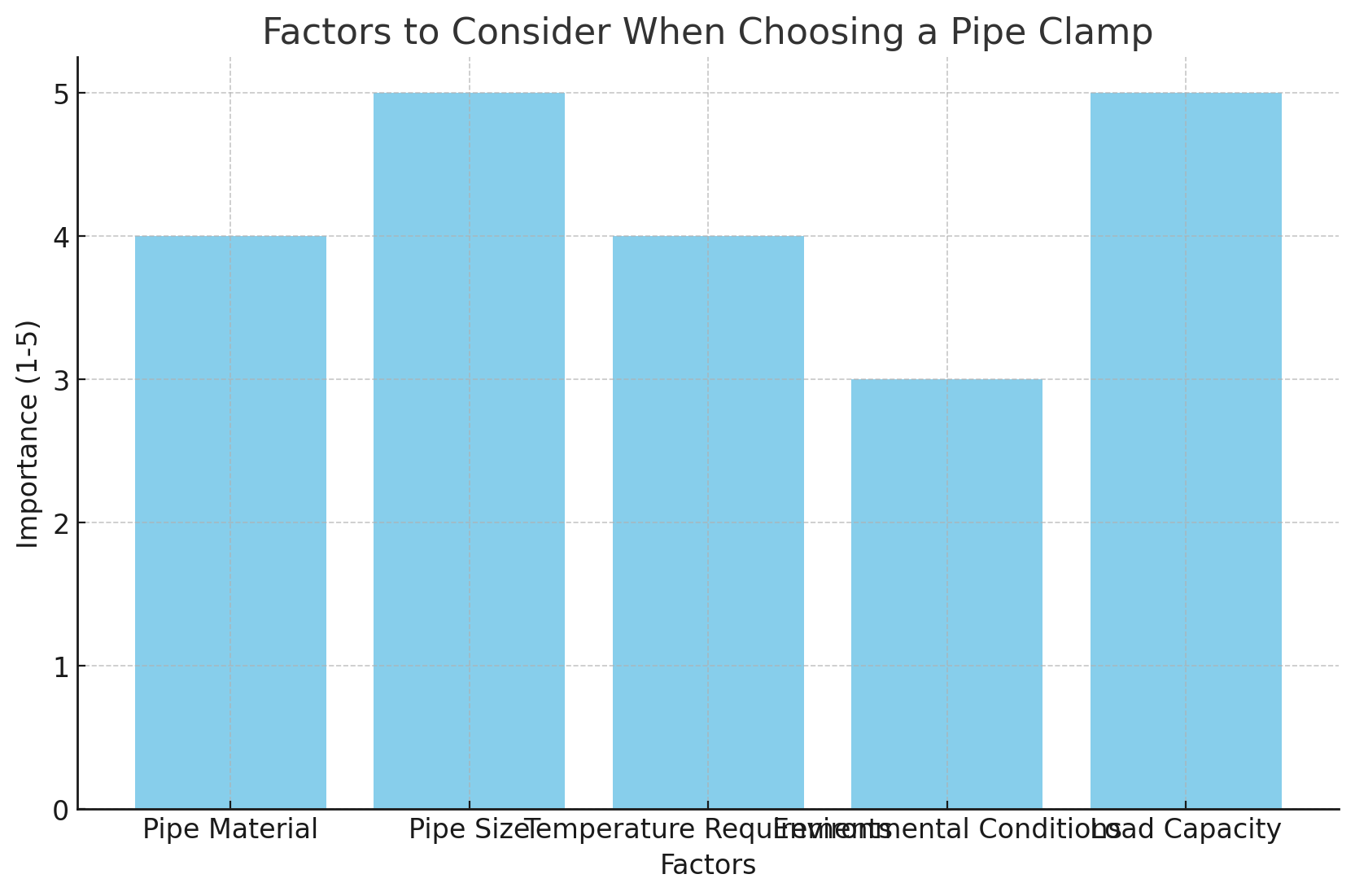

Key Factors to Consider When Choosing a Pipe Clamp

Pipe Material

The material of the pipe being secured significantly impacts the type of pipe clamp to be used. Different materials respond differently to temperature changes, chemical exposure, and mechanical stress. For example:

● PVC Pipes: PVC pipes expand and contract with temperature changes, so choosing a flexible clamp that allows for slight movement is important. A rubber-lined PVC clamp is ideal in this case.

● Copper Pipes: Copper is susceptible to corrosion when in contact with other metals, so using copper or brass clamps prevents galvanic corrosion.

● Steel Pipes: Steel pipes require robust clamps that can handle high loads and resist corrosion. Stainless steel clamps are most suitable here.

When choosing a pipe clamp, always match the material of the clamp with the material of the pipe to prevent damage and ensure long-term functionality.

Pipe Size and Clamp Fit

Proper sizing is critical when selecting a pipe clamp. A clamp that is too large or too small will fail to provide adequate support. Here's how to ensure a proper fit:

● Measure the Pipe Diameter: The inner diameter of the clamp must match the outer diameter of the pipe. This ensures a snug fit and prevents movement.

● Allow for Expansion: Pipes expand and contract due to temperature changes. Some clamps, such as those made by Walraven, allow for movement and are adjustable to accommodate these changes.

It is important to note that some clamps are designed for specific standard pipe sizes, so make sure you check the manufacturer's specifications before purchasing.

Temperature and Load Requirements

Pipe clamps are subject to varying loads and temperature conditions. When choosing a clamp, consider the following:

● Temperature Range: Pipes carrying hot or cold fluids will expand and contract with temperature changes. Pipe clamps must be able to handle these fluctuations without compromising their ability to secure the pipe.

● Maximum Load: For heavy-duty applications, such as in industrial or high-pressure systems, choose pipe clamps that have been tested for maximum load capacities. Ensure the clamp is rated to handle the expected weight and pressure of the pipe and its contents.

Failing to account for these factors may result in pipe damage, leaks, or system failure.

Environmental Conditions

Consider the environmental conditions in which the pipe clamp will be used:

● Indoor vs. Outdoor Use: Outdoor installations require clamps with corrosion-resistant coatings, such as galvanized or stainless steel, due to exposure to weather conditions.

● Chemical Exposure: If the clamp will be exposed to chemicals, choose materials that resist chemical corrosion. Plastic or rubber-lined clamps are often best suited for these conditions.

● Extreme Weather: In regions with extreme temperatures, such as very hot or cold environments, you’ll need pipe clamps that can withstand these conditions without degrading.

Choosing a clamp designed for the specific environment will extend its lifespan and ensure the stability of the piping system.

Factor | Description | Importance |

Pipe Material | Type of material (PVC, copper, steel) affects clamp choice. | Ensure compatibility with the pipe. |

Pipe Size | Clamp size should match the pipe’s diameter. | Ensures secure fit and prevents leaks. |

Temperature Requirements | Clamps must withstand the temperature range of the pipe’s operation. | Prevents expansion or contraction issues. |

Environmental Conditions | Exposure to chemicals, moisture, or extreme weather. | Affects clamp material choice. |

Load Capacity | Ensure the clamp can handle the pipe's weight and pressure. | Crucial for safety and durability. |

Types of Pipe Clamps and Their Applications

Standard Pipe Clamps

These are the most common types of pipe clamps, typically used for general applications. They include:

● Single-Screw Clamps: Simple, cost-effective clamps used for lightweight pipes in plumbing and HVAC systems.

● Two-Screw Clamps: Offer more secure support for pipes with heavier loads or in more demanding environments.

Standard pipe clamps are best for systems that don’t experience high pressures or require specialized features like temperature resistance.

Heavy-Duty Pipe Clamps

Heavy-duty pipe clamps are designed for high-pressure or industrial applications. They are typically larger, stronger, and made from more durable materials like stainless steel. These clamps are often used in:

● Oil and gas pipelines

● High-pressure water systems

● Large industrial plants

These clamps are built to handle heavier loads and more extreme operating conditions.

Adjustable Pipe Clamps

Adjustable pipe clamps are versatile options for systems that require flexibility. These clamps can fit a range of pipe sizes and provide secure support even if the pipe diameter changes. They're ideal for installations where future changes might be necessary, such as:

● Construction sites

● Temporary plumbing installations

They are perfect when you need a one-size-fits-all solution for varying pipe sizes.

Corrosion-Resistant Pipe Clamps

For applications where the piping system is exposed to moisture, chemicals, or harsh weather, corrosion-resistant pipe clamps are essential. These clamps are made from materials that can withstand rust and degradation, such as:

● Stainless Steel Clamps

● Galvanized Steel Clamps

● Plastic-Coated Clamps

Choosing corrosion-resistant clamps will extend the life of your piping system, especially in outdoor or industrial environments.

Type | Best Suited For | Features |

Standard Pipe Clamps | General plumbing and HVAC | Cost-effective, easy to install |

Heavy-Duty Pipe Clamps | Industrial, high-pressure systems | Stronger grip, handles large pipes |

Adjustable Pipe Clamps | Varying pipe sizes, flexible installations | Adjustable for different pipe diameters |

Corrosion-Resistant Pipe Clamps | Outdoor, chemical-exposed environments | Durable, ideal for harsh conditions |

Pipe Clamp Installation Considerations

Installation Process Overview

The installation of pipe clamps should follow a few key steps to ensure proper function:

1. Measure the Pipe: Confirm the pipe size and allow for expansion and contraction.

2. Select the Right Clamp: Choose a clamp that fits the pipe securely and matches environmental requirements.

3. Mount the Clamp: Attach the clamp to a wall or ceiling using screws or bolts, ensuring it is securely fastened.

4. Tighten the Clamp: Tighten the clamp to hold the pipe in place, but avoid over-tightening to prevent damage.

Proper installation is crucial to ensure that the clamp will hold the pipe securely without damaging it.

Tools and Accessories Required

To install a pipe clamp properly, you will need:

● Screws or Bolts: To secure the clamp to a wall or surface.

● Wrenches: For tightening the clamps.

● Measuring Tape: To ensure proper sizing.

● Rubber Gaskets (optional): To prevent wear or corrosion, especially when using metal clamps.

Tool/Accessory | Purpose | Importance |

Screws | Used to secure the clamp to a surface | Essential for proper installation |

Wrenches | Tighten screws for a secure fit | Prevents over-tightening or under-tightening |

Measuring Tape | Ensures accurate pipe and clamp sizing | Crucial for proper fit |

Rubber Pads | Protects pipes from damage during installation | Reduces risk of pipe damage |

Maintenance and Inspection

It is important to periodically inspect pipe clamps to ensure they remain secure and functional. Look for signs of wear, rust, or corrosion, and replace the clamps if necessary. Regular maintenance can prevent costly repairs down the road.

Price vs. Quality: How to Choose the Right Pipe Clamp within Budget

Understanding Clamp Costs

The cost of pipe clamps varies widely depending on the material, size, and load capacity. While plastic and standard steel clamps tend to be more affordable, heavy-duty or corrosion-resistant options can be more expensive.

Consider the overall cost of the piping system, including potential maintenance and replacement costs. Investing in high-quality clamps may save money in the long term by ensuring the longevity of the system.

Balancing Price and Durability

When choosing a pipe clamp, balancing price and durability is essential. While it may be tempting to opt for the cheapest option, consider the potential costs of replacing damaged clamps or dealing with pipe failures. For critical systems, invest in durable clamps that offer long-lasting performance.

Conclusion

Choosing the right pipe clamp requires careful consideration of factors like pipe material, size, and environmental conditions. The right clamp ensures a secure and long-lasting piping system.

Selecting a high-quality pipe clamp is crucial for efficiency and safety. Always match the clamp to your project’s specific needs.

For optimal performance, consult with experts like WEIHENG to choose the best pipe clamp solution for your system.

FAQ

Q: What is a Pipe Clamp used for?

A: A Pipe Clamp is used to secure pipes in place, ensuring they remain stable and functional. It's essential in plumbing, HVAC, and industrial applications.

Q: How do I choose the right Pipe Clamp?

A: Consider factors such as pipe material, size, temperature range, and environmental conditions when selecting a Pipe Clamp to ensure it fits your system's needs.

Q: Are Pipe Clamps available in different materials?

A: Yes, Pipe Clamps are made from various materials like stainless steel, plastic, and galvanized steel, each suited for different environmental and load requirements.

Q: What size Pipe Clamp do I need?

A: The Pipe Clamp size should match the pipe's diameter. It’s essential to account for any expansion or contraction due to temperature changes.

Q: Can I use a Pipe Clamp outdoors?

A: For outdoor use, select a corrosion-resistant Pipe Clamp, like those made from stainless steel or coated materials, to withstand weather conditions.

Q: Do Pipe Clamps require maintenance?

A: Yes, regular inspections for wear and corrosion are necessary, especially in critical applications, to maintain the clamp's effectiveness.

Q: How much does a Pipe Clamp cost?

A: The price of a Pipe Clamp varies based on material, size, and load capacity. It's important to balance cost with durability and functionality for your needs.