Introduction

Pipe clamps are essential for reliable plumbing and repairs. But what happens when they slip? Slippage can lead to incomplete seals and cause damage to the project.

In this article, we will discuss why pipe clamps slip, how to prevent it, and actionable tips for ensuring stable, long-lasting pipe repairs. You'll learn how to avoid slipping and improve your pipe clamp performance.

Understanding Pipe Clamps and Their Mechanisms

What Are Pipe Clamps?

Pipe clamps are mechanical devices designed to secure pipes in place, preventing movement and creating a tight seal. Typically made from durable materials like stainless steel, they come in various types, each suited for specific tasks. For example, saddle clamps are often used to fix pipes onto surfaces, while repair clamps seal cracks or leaks.

Key Types of Pipe Clamps:

● Saddle Clamps: These clamps are ideal for securing pipes to a surface and ensuring stability.

● Repair Clamps: Used specifically for fixing leaks or cracks, they wrap around the damaged pipe and provide a temporary or permanent seal.

● Stand-Off Clamps: Common in applications requiring space between the pipe and its surrounding surfaces, offering additional support and stability.

Each of these clamps functions slightly differently but follows the same general principle: applying pressure to create a secure seal, preventing leaks, and ensuring stability.

How Do Pipe Clamps Work?

Pipe clamps work by applying pressure around the circumference of a pipe, typically using a combination of adjustable straps or metal bands, and often incorporating a rubber gasket for added sealing. The mechanism is simple: when tightened, the clamp squeezes the pipe tightly, ensuring a snug fit and preventing any movement.

Factors Affecting Pipe Clamp Effectiveness:

● Pressure: A clamp must exert enough pressure to hold the pipe in place without damaging it or compromising the seal.

● Pipe Material: Some materials, such as PVC or metal, require different types of pipe clamps due to their varying flexibility and durability.

● Clamp Design: The design of the pipe clamp, including the size, shape, and material, affects its ability to securely fit and function effectively.

By understanding these key components, it becomes easier to determine why a pipe clamp might slip or fail to hold, and how to fix these issues before they compromise the project.

Pipe Clamp Type | Application |

Saddle Clamps | Used to repair holes or cracks in pipes. |

Repair Clamps | Ideal for fixing damaged sections of pipes under pressure. |

Stand-Off Clamps | Used for pipes that require a clamp to sit off the surface. |

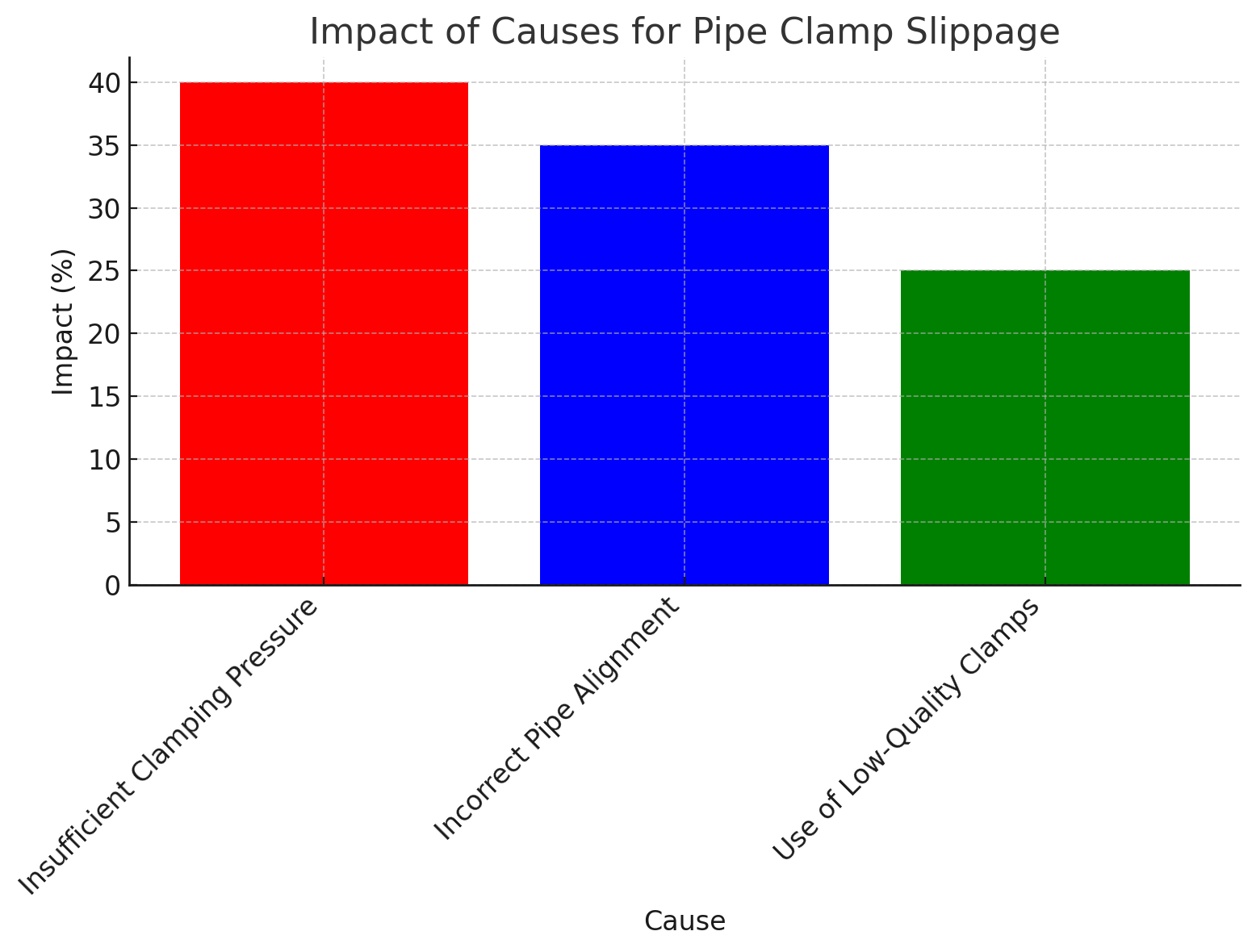

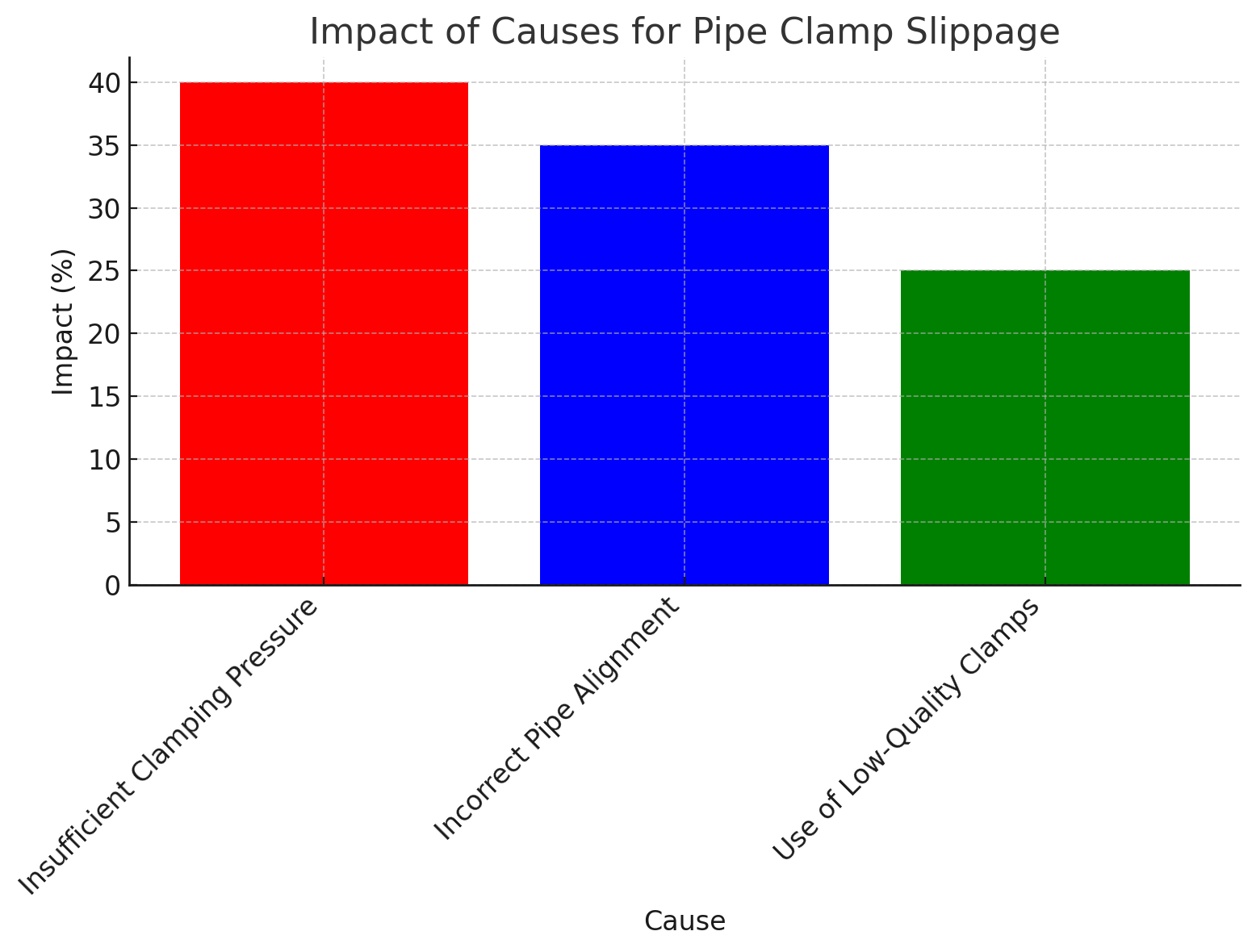

Causes of Pipe Clamps Slipping

Insufficient Clamping Pressure

One of the primary reasons for pipe clamp slippage is insufficient pressure. If a pipe clamp does not apply enough force to compress the pipe and form a secure seal, it may slip when the system is under pressure or during installation. This can lead to leaks, weakened joints, or further damage to the pipe.

Signs of Insufficient Pressure:

● Visible movement of the clamp when the system is turned on.

● Leaks appearing even after the clamp has been installed.

● Difficulty in tightening the clamp to the desired level.

Ensuring that the correct amount of pressure is applied is crucial for avoiding these issues.

Sign | Explanation |

Pipe Leakage | Insufficient pressure can result in leakage at the connection point. |

Movement of the Clamp | If the clamp moves when the pipe is in use, pressure is likely too low. |

Gaps Between Clamp and Pipe | A loose clamp will leave gaps, indicating insufficient pressure. |

Incorrect Pipe Alignment

Another common cause of pipe clamp slippage is improper alignment. If the clamp is not positioned correctly, the pressure is unevenly distributed, which can lead to slippage or an incomplete seal. Misalignment often occurs due to incorrect measurement or inadequate tools for positioning the clamp.

How Misalignment Affects Clamping:

● It creates uneven pressure distribution, resulting in weak spots on the pipe.

● Can lead to pipe damage, such as bending or warping.

● Increases the likelihood of future leaks or failures in the system.

Correct alignment is essential for ensuring the clamp holds securely and performs as intended.

Use of Low-Quality Clamps

The quality of the pipe clamp itself plays a significant role in preventing slippage. Low-quality clamps made from weaker materials or poorly designed components are more prone to wear and slippage, especially when under pressure.

Risks of Using Low-Quality Pipe Clamps:

● Inadequate tension and compression.

● Decreased lifespan of the clamp, leading to early failure.

● Increased risk of leakage and system instability.

Choosing high-quality, durable pipe clamps designed for the specific application helps reduce these risks and ensures a longer-lasting solution.

Cause | Explanation |

Insufficient Clamping Pressure | Low pressure can cause the clamp to lose its grip, leading to slipping. |

Incorrect Pipe Alignment | Misalignment prevents the clamp from forming a secure seal, causing it to slip. |

Use of Low-Quality Clamps | Poor materials or design can reduce clamp effectiveness, leading to slippage. |

How to Keep Pipe Clamps from Slipping

Ensure Proper Clamping Pressure

To prevent slippage, it’s important to apply enough clamping pressure while avoiding over-tightening. Over-tightening can damage the pipe or lead to an improper seal, but under-tightening will not secure the clamp properly. Using a torque wrench can help apply the correct amount of pressure for the job.

Tips for Proper Tightening:

● Use a torque wrench to ensure consistent pressure without over-tightening.

● Gradually tighten the clamp in stages rather than applying all the pressure at once.

● Periodically check the clamp for signs of loosening or movement during installation.

Achieving the perfect balance between pressure and comfort ensures a strong, secure fit that prevents slipping.

Proper Alignment of Pipe and Clamp

Aligning the pipe correctly is essential for preventing slippage. Misaligned pipes may cause uneven pressure or gaps in the seal, leading to failure.

Steps for Proper Alignment:

● Double-check measurements before installation.

● Use pipe alignment jigs or markers to ensure the clamp is positioned properly.

● Avoid twisting or bending the pipe during installation.

Proper alignment guarantees that the clamp applies even pressure across the entire surface, reducing the chances of slipping.

Choosing High-Quality Pipe Clamps

Investing in high-quality pipe clamps is one of the most effective ways to prevent slippage. Opt for clamps made from durable materials like stainless steel, which provide superior grip and can withstand higher pressures. These clamps are more resistant to slippage and offer better long-term performance.

Choosing the Right Clamp:

● For high-pressure systems, choose clamps that are specifically rated for such applications.

● Select clamps with adjustable features to accommodate different pipe sizes.

● Consider corrosion-resistant clamps for outdoor or harsh environments.

High-quality clamps ensure reliable performance and minimize the risk of slippage under pressure.

Enhancing the Surface Grip

Increasing the surface grip between the clamp and the pipe can prevent slipping, especially in challenging conditions. Using rubber pads or textured materials can improve the friction between the clamp and the pipe surface.

Methods to Improve Friction:

● Attach rubber pads or non-slip surfaces inside the clamp for better grip.

● Use textured adhesive materials to increase friction on smooth pipes.

● For oily or wet environments, consider using silicone-based clamp liners to provide extra grip.

These additional measures can significantly reduce the chances of a clamp slipping and ensure a tight, stable connection.

Method | Action |

Ensure Proper Clamping Pressure | Apply the correct pressure without over-tightening. |

Correct Pipe Alignment | Ensure the clamp is properly aligned with the pipe. |

Choose High-Quality Clamps | Use durable materials like stainless steel for better grip. |

Enhance Surface Grip | Use rubber pads or textured materials to increase friction. |

Best Practices for Installing Pipe Clamps

Preparing the Pipe Surface

Before installing a pipe clamp, ensure the surface of the pipe is clean and free from debris, rust, or other materials that could prevent a secure fit. Dirty or damaged surfaces can reduce the effectiveness of the clamp and lead to slippage.

Steps for Preparing the Pipe:

● Clean the pipe thoroughly using a wire brush or solvent.

● Remove any sharp edges or burrs using a deburring tool.

● Inspect the pipe for cracks or signs of damage that could affect the clamp’s performance.

Proper pipe preparation is essential for achieving a stable, leak-free connection.

Using Additional Clamping Aids

For larger pipes or complex installations, additional clamping aids can help maintain the stability of the pipe clamp. Brackets, stabilizers, or auxiliary supports can provide extra support and reduce the chances of slippage, especially in larger diameter pipes or when multiple clamps are needed.

Additional Tools to Consider:

● Pipe brackets for added stability.

● Pipe supports to distribute weight evenly and prevent movement.

● Temporary clamping aids to hold the pipe in place during installation.

Using these aids can help distribute pressure evenly, preventing pipe clamps from slipping and improving the overall success of the installation.

Troubleshooting Common Pipe Clamp Issues

Slippage After Installation

If you notice that a pipe clamp has slipped after installation, there are several troubleshooting steps to take.

Steps to Fix Slippage:

● Inspect the clamp for signs of wear or damage.

● Check the alignment and reposition the clamp if necessary.

● Re-tighten the clamp to the correct pressure using a torque wrench.

Reapplying the clamp correctly and ensuring proper pressure will restore its effectiveness and prevent further slippage.

Long-Term Maintenance to Prevent Slipping

Routine maintenance and periodic inspections of pipe clamps are essential for preventing slippage over time. Regular checks for wear, corrosion, or loosening can help ensure that clamps continue to perform optimally.

Maintenance Tips:

● Regularly inspect clamps for signs of corrosion or rust.

● Clean clamps to remove dirt, debris, or build-up that could affect functionality.

● Replace worn or damaged clamps promptly to maintain the seal.

By maintaining the clamps properly, you can prevent slipping and ensure the continued stability of the system.

Conclusion

Preventing pipe clamp slippage is vital for secure, reliable repairs. By applying proper pressure, ensuring correct alignment, and using high-quality clamps, slipping can be minimized. Regular maintenance and the right installation practices further enhance clamp effectiveness. For long-lasting, leak-free connections, investing in top-quality clamps like those from WEIHENG is essential. Their durable, reliable products provide excellent value for your pipe repair needs.

FAQ

Q: What causes pipe clamps to slip during installation?

A: Pipe clamps can slip due to insufficient clamping pressure, poor alignment, or using low-quality clamps. Ensuring proper pressure and alignment can prevent this.

Q: How can I prevent a pipe clamp from slipping?

A: To prevent slippage, ensure proper clamping pressure, align the clamp correctly, and use high-quality materials like stainless steel for better grip.

Q: Can I use any pipe clamp for all types of pipes?

A: No, choosing the right pipe clamp depends on the pipe's material and size. Ensure compatibility for effective sealing and stability.

Q: Why is pressure important when using pipe clamps?

A: Sufficient pressure ensures a tight seal, preventing leaks and slippage. Too little pressure may lead to insecure clamping, while over-tightening can damage the pipe.

Q: How often should I maintain pipe clamps to avoid slipping?

A: Regular inspections and maintenance, such as cleaning and lubricating, help maintain the effectiveness of pipe clamps and prevent slippage over time.