Have you ever wondered if stainless steel is suitable for gas piping? With its reputation for durability and corrosion resistance, stainless steel is a material often considered for a variety of industrial applications. But when it comes to something as critical as gas lines, choosing the right material is essential for ensuring safety and long-term functionality.

In this post, we’ll discuss the properties of stainless steel, its suitability for gas piping, and the specific benefits it brings to this application. You will learn why this material is gaining popularity in the plumbing industry and how it stacks up against other commonly used materials for gas lines.

Why Consider Stainless Steel for Gas Pipes?

When designing or installing gas systems, whether in residential, commercial, or industrial applications, it’s important to choose a material that can withstand high pressures, resist corrosion, and handle exposure to various environmental conditions. Traditional materials like black iron and copper have been the go-to for gas lines, but modern advancements and growing concerns about safety and longevity have made stainless steel a compelling option.

Key Benefits of Stainless Steel Pipes

Corrosion Resistance: Stainless steel is known for its superior resistance to corrosion compared to other metals, such as copper or black steel. This makes it ideal for use in environments where the piping will be exposed to moisture or other corrosive substances, which can significantly reduce the lifespan of other materials.

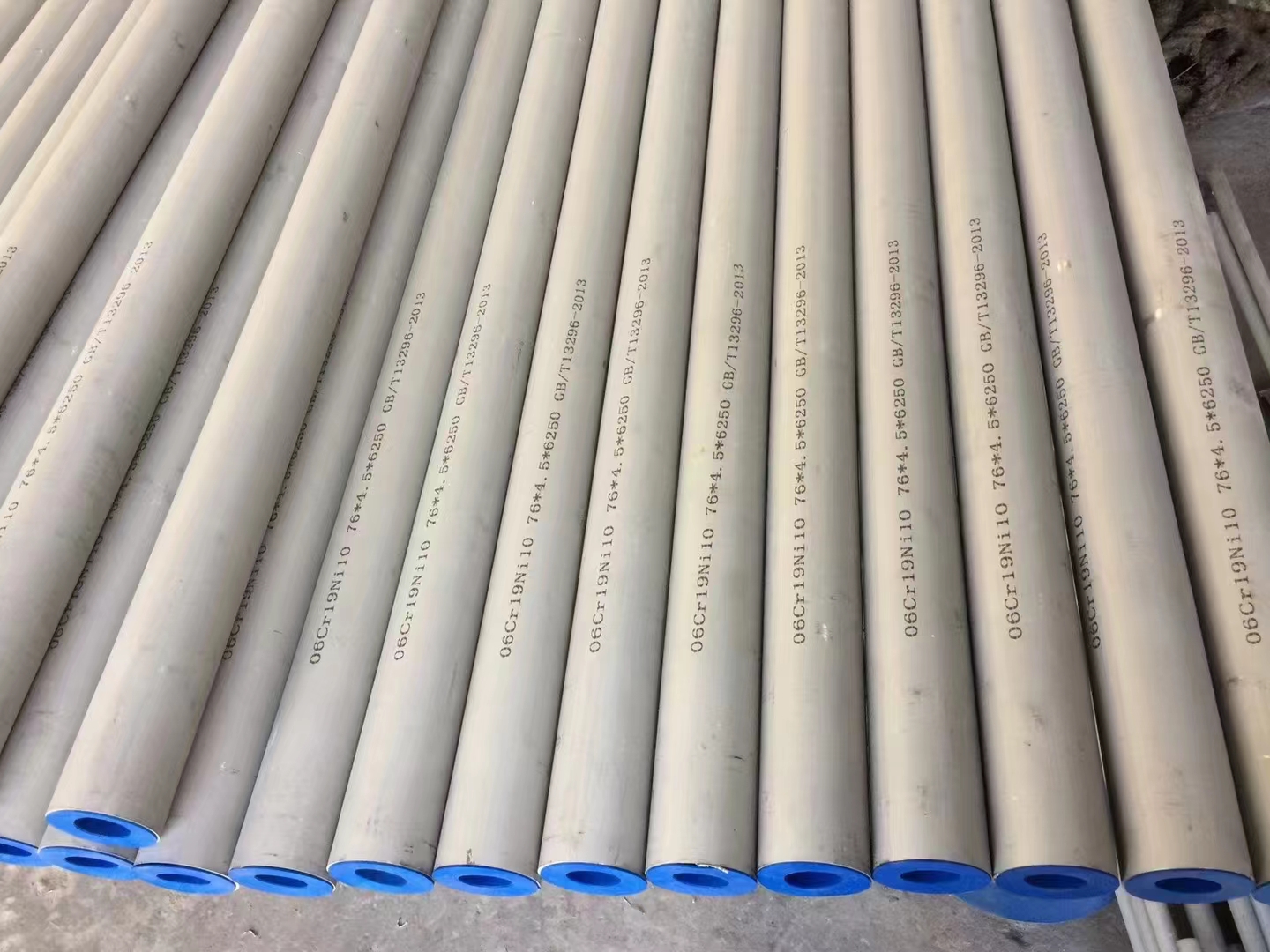

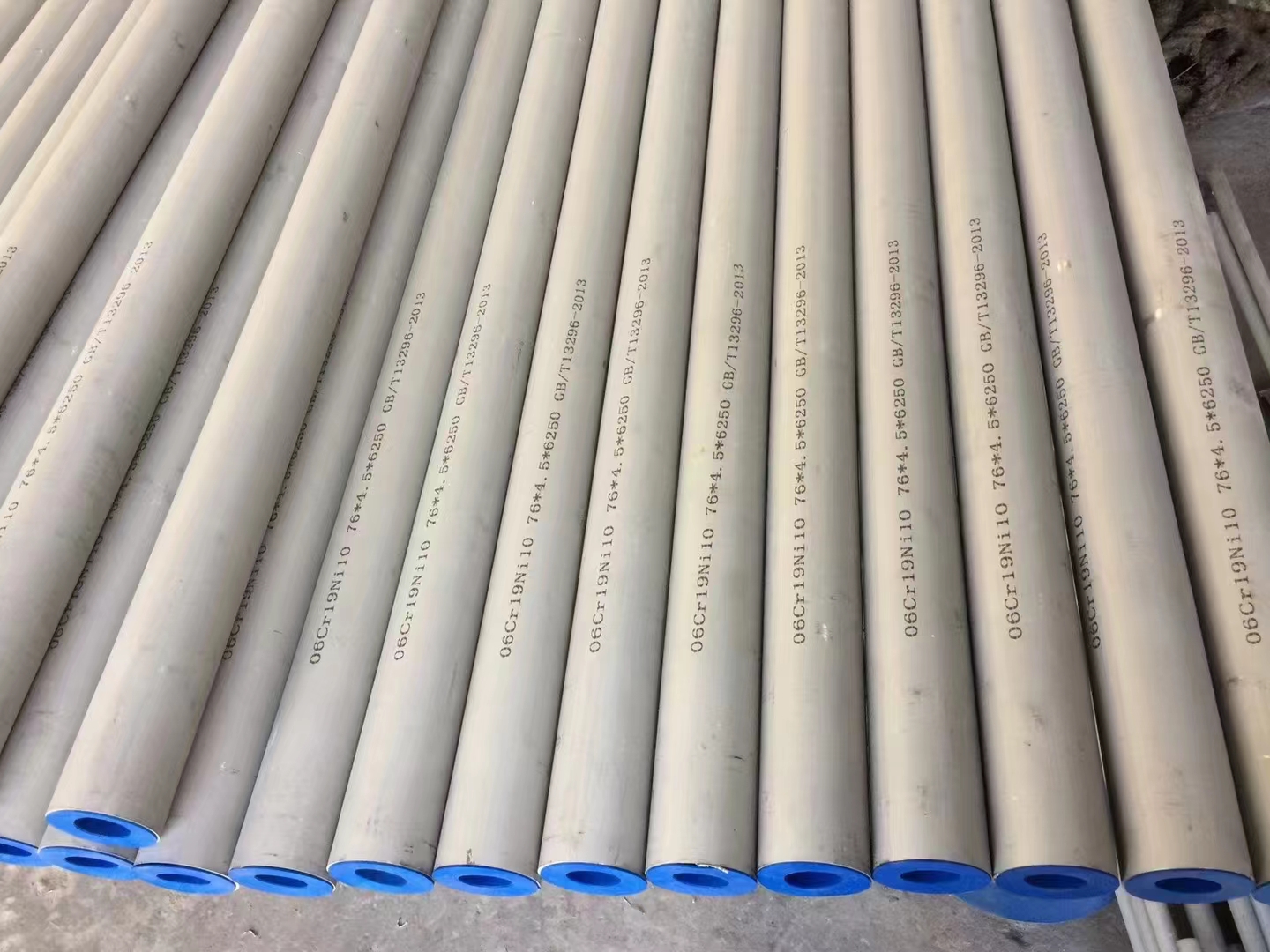

Strength and Durability: Stainless steel pipes are designed to withstand high pressures and extreme temperatures, which makes them suitable for both residential and industrial gas lines. The material’s structural integrity ensures a reliable, long-lasting solution.

Longer Lifespan: One of the most significant advantages of stainless steel is its ability to last longer than traditional materials. With minimal maintenance required, stainless steel pipes can provide a service life of up to 50 years, depending on the installation environment.

Fire Resistance: Stainless steel can withstand high temperatures without deteriorating, which makes it an excellent choice for gas lines that need to maintain their integrity even in the event of a fire.

Leak Prevention: The high strength of stainless steel pipes ensures that they are more resistant to cracks or leaks, providing additional safety for gas systems, which are sensitive to leakage and could pose significant risks.

Stainless Steel vs. Other Gas Pipe Materials

While stainless steel offers several advantages, it is not the only material used in gas pipelines. Here’s a comparison of stainless steel with other common piping materials:

| Material | Pros | Cons |

| Stainless Steel | Highly durable, resistant to corrosion, fire-resistant | Expensive compared to black iron and copper |

| Black Steel | Cost-effective, widely used | Prone to corrosion over time, short lifespan |

| Copper | Flexible, easy to install | Expensive, can corrode with certain gases |

| Polyethylene (PE) | Lightweight, flexible, recyclable | Less durable, can be damaged by physical impact |

Applications of Stainless Steel in Gas Pipelines

1. Natural Gas Lines

Stainless steel is commonly used in natural gas systems, both for residential and commercial use. Its ability to withstand high pressure and resist corrosion makes it an ideal choice for gas lines that need to handle fluctuating pressures and extreme conditions.

2. Propane Gas Systems

For propane systems, stainless steel offers long-lasting protection against the harsh chemicals and substances typically found in propane gas. Its fire resistance also makes it a safer option in environments where fire hazards are a concern.

3. Industrial Gas Pipelines

In industrial settings, where gas lines are exposed to higher temperatures and more aggressive chemicals, stainless steel’s robust properties are a perfect match. Whether it’s for refining, chemical plants, or other industrial applications, stainless steel can offer unmatched durability and safety.

Considerations When Installing Stainless Steel Gas Pipes

While stainless steel is an excellent choice for gas systems, several factors need to be considered when selecting and installing these pipes:

1. Pressure Rating

Stainless steel pipes come with different pressure ratings based on their thickness and grade. It’s crucial to ensure that the chosen pipe can handle the specific pressure requirements of your gas system to avoid failures or leaks.

2. Installation Complexity

Installing stainless steel gas pipes can be more complex than traditional piping systems. This material requires specialized fittings and tools, and the installation process may take longer compared to other materials like polyethylene. However, the benefits of durability and safety often outweigh these challenges.

3. Cost Considerations

One of the major drawbacks of using stainless steel for gas pipelines is the cost. Stainless steel is generally more expensive than other materials, such as black steel or copper. However, its long-term benefits, such as reduced maintenance and a longer lifespan, often make it a cost-effective solution in the long run.

4. Local Codes and Regulations

Before installing stainless steel pipes for gas lines, it's important to check local codes and regulations. In some regions, certain types of stainless steel or installation methods may not be approved for gas systems.

Future Trends in Stainless Steel Gas Piping

As gas systems become more complex and safety becomes a higher priority, the use of stainless steel is expected to grow. With advancements in manufacturing technology, stainless steel pipes are becoming more affordable and easier to install, making them a more attractive option for a wider range of gas applications.

1. Integration with Smart Technologies

The integration of smart technologies in gas systems, such as leak detection sensors and monitoring systems, will enhance the safety and efficiency of stainless steel piping systems. These technologies can help detect potential issues early, ensuring that the system remains safe and operational.

2. Increased Demand in Industrial Applications

With industrial processes becoming more energy-intensive, the need for durable and safe gas piping systems will increase. Stainless steel’s ability to handle high pressures and temperatures makes it an ideal candidate for these demanding applications.

Conclusion

In conclusion, stainless steel is not only a reliable and durable material for gas pipelines but also an excellent choice for ensuring safety and longevity in both residential and industrial gas systems. While its higher initial cost may deter some, the long-term benefits, including superior corrosion resistance, fire resistance, and a longer lifespan, make it a wise investment. Whether you're installing a new system or upgrading an existing one, stainless steel pipes provide an unparalleled solution for today’s gas piping needs.

If you're looking for high-quality stainless steel products for your gas piping systems, consider the products offered by WEIHENG, known for their reliability and superior performance.

FAQ

Q: Can stainless steel be used for natural gas piping?

A: Yes, stainless steel is a durable and corrosion-resistant material, making it suitable for natural gas piping.

Q: How long do stainless steel gas pipes last?

A: Stainless steel gas pipes can last up to 50 years or more, depending on the environment and installation.

Q: Are stainless steel pipes better than black steel for gas systems?

A: Yes, stainless steel offers superior corrosion resistance and durability compared to black steel.

Q: Can stainless steel gas pipes handle high pressure?

A: Stainless steel pipes are ideal for high-pressure gas applications, making them suitable for industrial use.

Q: Is it difficult to install stainless steel gas pipes?

A: Installing stainless steel pipes requires specialized tools and expertise, but it is worth the investment due to their long lifespan and durability.