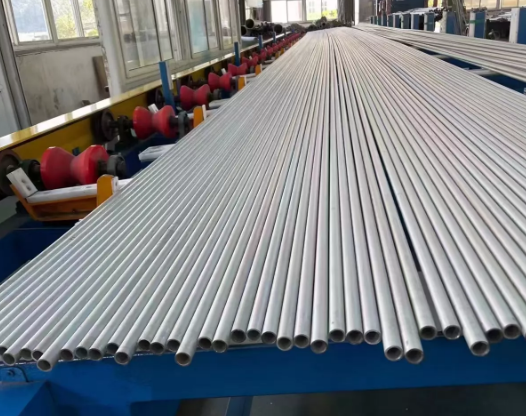

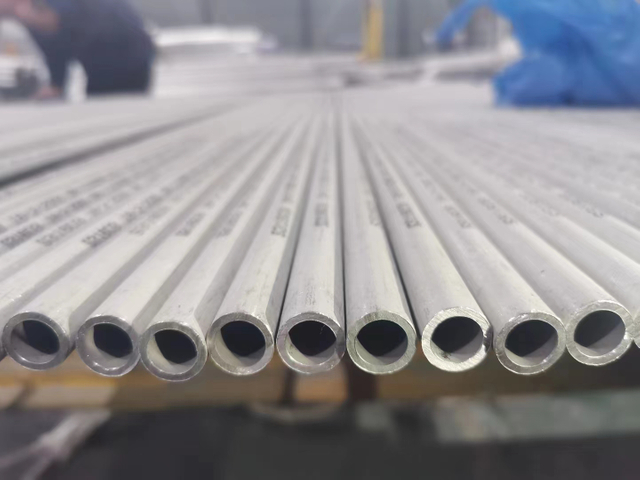

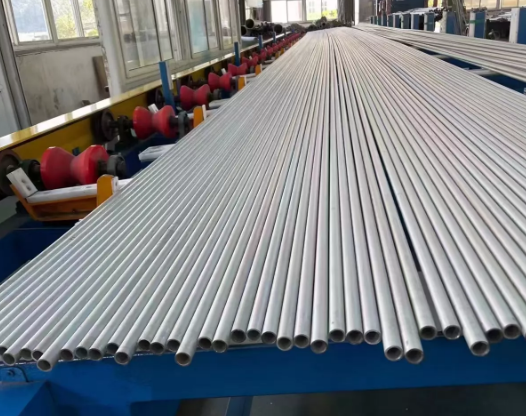

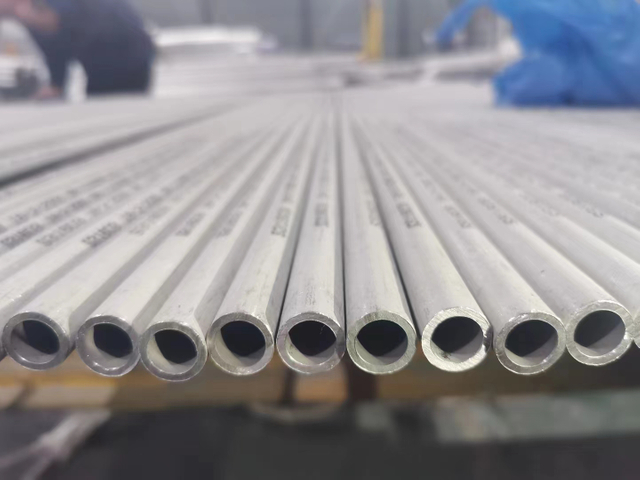

Bending stainless steel pipe is essential in many industries, from food processing to plumbing. Whether you're working with exhaust systems or structural applications, choosing the right bending method is crucial. In this article, we'll explore why it's important to select the correct technique and guide you through the best practices for bending stainless steel pipes effectively.

Core Methods of Bending Stainless Steel Pipe

There are several ways to bend stainless steel pipe, each method offering distinct advantages based on the pipe's size, wall thickness, and the specific needs of your project. Below are the most common methods for bending stainless steel pipe:

Mandrel Bending

Best for Precision and Smooth Bends

Mandrel bending is the go-to method for producing the smoothest, most precise bends. It is perfect for situations where the pipe's appearance and functionality must remain flawless.

Ideal for Small to Medium Diameter Pipes (½–4 Inches)

This technique works best for pipes with a diameter between ½ and 4 inches, particularly those with thinner walls. It helps prevent kinking or collapsing during the bending process.

Used in Visible Applications

Due to its ability to maintain smooth curves, mandrel bending is commonly used in visible applications, such as food-grade piping or exhaust systems, where the bend's appearance is critical.

Compression Bending

Cost-Effective for Larger, Simpler Bends

Compression bending is a more affordable method compared to mandrel bending and is best suited for larger, simpler bends. This technique is ideal when precision is not the primary concern.

Works for Pipes with Diameters from 1–5 Inches

This method can accommodate pipes ranging from 1 to 5 inches in diameter, making it suitable for medium-sized pipes often found in industrial plumbing or structural systems.

Suitable for Industrial Plumbing and Structural Uses

Compression bending is commonly used in applications where strength and function are more important than aesthetics. It is ideal for industrial plumbing systems or structural frameworks.

Heat Bending

Perfect for Thick-Walled or Large-Diameter Pipes (Greater Than 5 Inches)

Heat bending is the best technique for large or thick-walled pipes, which are difficult to bend without the aid of heat. The pipe is heated to make it more pliable and easier to bend.

Uses Heat to Enhance Pipe Flexibility

Heat bending works by applying controlled heat (around 800–1000°C) to the bending area, which makes the pipe more flexible. This technique is essential for creating complex bends in large pipes.

Precautionary Steps to Avoid Overheating and Damage

It’s crucial to carefully monitor the heat to avoid overheating the pipe, as excessive heat can weaken it. After bending, the pipe must be cooled slowly to preserve its strength.

Manual Bending

DIY Method Using Manual Tools for Small-Scale Projects

Manual bending is a hands-on method that works well for small, simple projects. It’s often used by DIYers or for small-scale tasks that don't require specialized equipment.

Ideal for Pipes with Smaller Diameters (≤1 Inch)

This method is most effective for pipes with smaller diameters (less than 1 inch). It’s perfect for thin-walled pipes where less force is needed to achieve the desired bend.

Step-by-Step Process for Gradual, Controlled Bends

Manual bending requires slow and steady pressure to avoid cracking the pipe. This process is ideal for making gradual bends in small pipes, ensuring precision and avoiding damage.

Bending Method | Ideal Pipe Size | Best For | Key Consideration |

Mandrel Bending | ½–4 inches, thin walls | Precision, visible applications | Requires specialized equipment |

Compression Bending | 1–5 inches, thicker walls | Cost-effective, industrial uses | Slight flattening on the inner bend |

Heat Bending | >5 inches, thick walls | Large, complex bends | Must control heating to avoid damage |

Manual Bending | ≤1 inch, thin walls | Small-scale projects, DIY | Slow, controlled pressure to prevent cracks |

By following these steps and taking care to use the right tools and techniques, you’ll be able to bend stainless steel pipe effectively and safely, whether for a professional project or a DIY task.

Common Bending Mistakes to Avoid

Bending stainless steel pipe can be tricky, and making the wrong move can lead to costly mistakes or damaged pipes. Avoiding common errors is key to ensuring a smooth and successful project. Here are some frequent bending mistakes to watch out for:

Skipping the Use of Support Tools

Risks of Not Using Mandrels or Spring Benders

When bending thin-walled pipes, it's essential to use support tools like mandrels or spring benders. Without them, the pipe can collapse under pressure, resulting in kinks or permanent deformation. Forcing the pipe to bend without support can ruin the functionality and appearance of the pipe, making it unsuitable for many applications.

Consequences of Collapsing and Functionality Loss

If the pipe collapses during bending, it may become unusable. This is particularly problematic in applications where the integrity of the pipe is crucial, such as in food processing or visible plumbing systems. Always use the right support tools to maintain the pipe’s shape and strength.

Overheating the Pipe

How Excessive Heat Weakens Stainless Steel

Heating stainless steel is often necessary for bending, but too much heat can cause damage. Overheating weakens the material, making it more likely to crack or corrode over time. This can lead to a brittle pipe, which may fail under pressure or wear out much faster.

Safe Temperature Guidelines to Prevent Overheating

For most stainless steel pipes, the heating temperature should range between 800°C to 1000°C (1472°F to 1832°F). Exceeding this temperature range can cause discoloration and degradation of the pipe’s structure. It’s important to monitor the pipe during the heating process to avoid overheating. Always use a heat gauge to ensure that the pipe is heated evenly and safely.

Forcing Sharp Bends

Importance of Not Exceeding the Pipe’s Minimum Bend Radius

Every pipe has a minimum bend radius, which is the tightest curve the pipe can handle without breaking. Forcing the pipe to bend tighter than its minimum radius can lead to cracks or fractures. Stainless steel is particularly prone to this because of its high tensile strength and lower flexibility compared to softer metals.

Methods for Achieving Gradual, Smooth Bends

To avoid forcing a sharp bend, always ensure that the bend is gradual. Use a bending tool that applies steady, even pressure to ensure the pipe bends smoothly without exceeding its minimum radius. If necessary, increase the length of the bend to ensure it remains smooth and continuous.Ignoring Wall Thickness

Why Thick-Walled Pipes Require More Force or Heat

Thick-walled pipes are more rigid than thin-walled pipes, meaning they require more force or heat to bend properly. When bending thick pipes, using manual tools may not be enough. Hydraulic or mechanical benders are usually needed for these types of pipes to avoid damaging the material or failing to achieve the desired bend.

Risks of Using Manual Tools for Thick Pipes

Manual benders are great for smaller, thinner pipes but may struggle with thick-walled pipes. Trying to bend thick-walled pipes without the right equipment can lead to incomplete bends, cracks, or a permanently damaged pipe. It’s crucial to use the appropriate tools for the thickness of the pipe.

Bending Mistake | Cause | Consequence | Solution |

Skipping Support Tools | No mandrels or spring benders | Collapsing, kinking, loss of function | Always use appropriate support tools |

Overheating the Pipe | Excessive heat | Cracking, corrosion, brittleness | Monitor heat, stay within safe range |

Forcing Sharp Bends | Exceeding minimum bend radius | Cracking or fractures | Apply gradual pressure, avoid sharp bends |

Ignoring Wall Thickness | Using manual tools for thick pipes | Incomplete bends, pipe damage | Use hydraulic or mechanical benders |

Tip: Avoiding these common mistakes will help ensure your stainless steel bending process is smooth and efficient. Whether you're working on a large industrial project or a small DIY task, taking the time to follow the correct procedures will save you time, money, and frustration in the long run.

Comparing Stainless Steel Pipe to Other Materials

When choosing materials for your pipe-bending projects, it’s essential to compare stainless steel with other common materials like mild steel and aluminum. Each has its own unique properties, and understanding their differences can help you make the best choice for your specific needs. Here’s a closer look at how stainless steel stacks up against mild steel and aluminum.

Stainless Steel vs. Mild Steel

Differences in Bending Difficulty and Tool Requirements

Stainless steel is tougher than mild steel, making it more difficult to bend. It has a higher tensile strength, meaning you need specialized tools like hydraulic or mandrel benders to achieve smooth bends. In contrast, mild steel is softer and easier to manipulate, requiring less force and simpler tools. For bending stainless steel, you may need more advanced machinery to ensure precision and avoid damaging the pipe.

Durability Comparisons, Especially Post-Bend

One of the main advantages of stainless steel is its superior durability. After bending, stainless steel retains its strength and resistance to corrosion, making it ideal for harsh environments like food processing or outdoor installations. Mild steel, on the other hand, tends to rust and deteriorate when exposed to moisture or corrosive substances, reducing its long-term viability. Even though it’s easier to bend, mild steel doesn’t offer the same level of performance and longevity as stainless steel, especially in high-demand applications.

Stainless Steel vs. Aluminum

Flexibility and Bending Challenges with Aluminum Pipes

Aluminum is much more flexible than stainless steel, making it easier to bend. However, this increased flexibility can be a disadvantage in certain situations. While aluminum pipes are lighter and can be bent with less force, they are more prone to kinking and damage during the bending process. Stainless steel, with its higher strength, offers more control over the bend, ensuring smooth curves without compromising the pipe’s integrity.

Why Stainless Steel is Preferred for High-Performance, Corrosion-Resistant Applications

Stainless steel is a clear winner when it comes to high-performance, corrosion-resistant applications. While aluminum offers some resistance to corrosion, it doesn't compare to stainless steel’s ability to withstand extreme environments. Stainless steel is preferred for critical applications in industries like aerospace, chemical processing, and food manufacturing, where corrosion resistance and durability are paramount. Aluminum is often chosen for lightweight, less demanding projects, but for long-term performance, stainless steel is the more reliable choice.

Material | Bending Difficulty | Durability Post-Bend | Ideal Use |

Stainless Steel | Higher, requires specialized tools | Excellent, resistant to corrosion | High-performance, harsh environments |

Mild Steel | Lower, easier to bend | Low, rusts easily | General-purpose, budget-friendly |

Aluminum | Easier, more flexible | Moderate, prone to wear | Lightweight applications, non-corrosive environments |

In general, the choice between stainless steel, mild steel, and aluminum depends on the specific requirements of your project. Stainless steel offers the best durability and performance, particularly for high-demand, corrosive environments. While mild steel is easier to bend, it doesn’t offer the same level of resistance and longevity. Aluminum, on the other hand, provides flexibility but lacks the strength and corrosion resistance of stainless steel.

Conclusion

Bending stainless steel pipe requires careful selection of the right technique, such as mandrel or heat bending. Using the appropriate method ensures smooth bends and prevents damage. The right bending approach guarantees durability, especially in demanding industrial and commercial environments. Stainless steel pipes offer long-lasting strength and resistance to corrosion, making them ideal for high-performance applications. For projects requiring high-quality materials, Weiheng provides products designed for excellent performance and durability, offering value with reliable solutions in various industries.

FAQ

Q: What is the best method for bending stainless steel pipe?

A: The best method depends on the pipe size and thickness. For precise bends, mandrel bending is ideal. For larger, thicker pipes, heat bending is preferred.

Q: Why is stainless steel pipe harder to bend than mild steel?

A: Stainless steel pipe has a higher tensile strength, making it more resistant to bending. It requires specialized tools and techniques to prevent cracking.

Q: Can I bend stainless steel pipe without special tools?

A: While it’s possible for small pipes, using tools like spring benders or hydraulic machines ensures smooth, accurate bends and prevents damage.

Q: What are the benefits of using stainless steel pipe in bending applications?

A: Stainless steel pipe offers excellent durability and corrosion resistance, making it ideal for high-performance applications, such as food processing and exhaust systems.