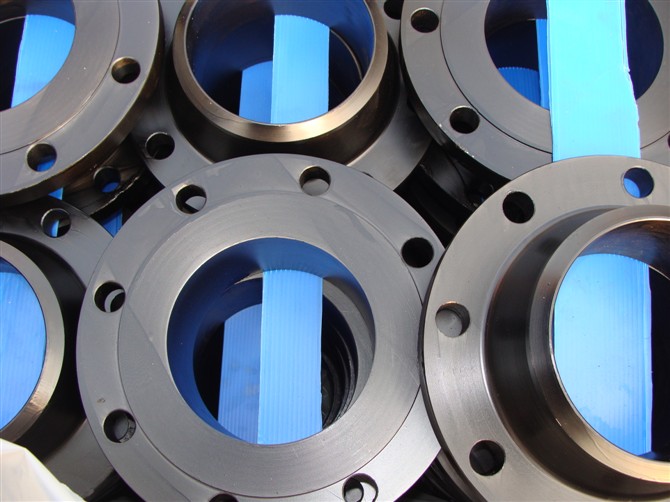

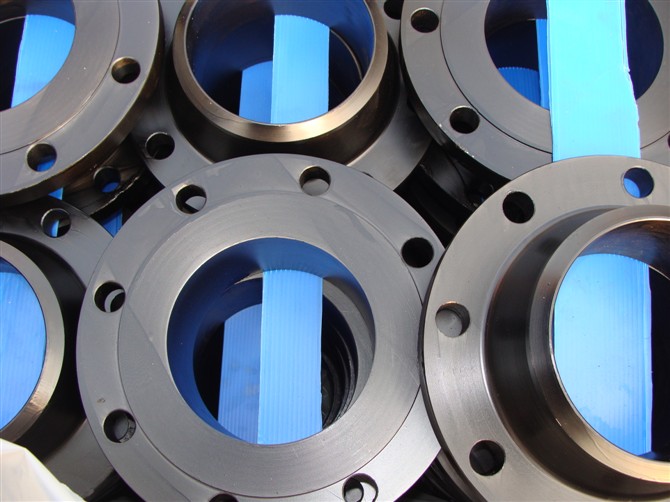

Understanding Schedule 80 Butt Weld Carbon Steel Pipe Fittings

Schedule 80 Butt Weld Carbon Steel Pipe Fittings are industrial-grade components designed to create strong, permanent connections in high-pressure piping systems. The “Schedule 80” label refers to their thick wall thickness—thicker than lighter schedules like Schedule 40—providing extra strength for demanding environments. The butt weld connection method involves fusing the fitting to the pipe via welding, resulting in a joint that’s as strong as the pipe itself. Made from high-quality carbon steel, these fittings are not just connectors; they’re critical for maintaining system integrity in industries where leaks or failures could lead to costly downtime or safety risks.

Core Advantages of Schedule 80 Butt Weld Carbon Steel Pipe Fittings

High-Pressure Tolerance

The Schedule 80 thickness is the key to their pressure resistance. The thick carbon steel walls withstand extreme internal pressure without bursting or deforming—essential for oil refineries, chemical plants, and power generation facilities where systems operate at hundreds of psi. This tolerance makes them far more reliable than thinner, lighter fittings in critical applications.

Permanent Leak-Proof Joints

Unlike threaded or flanged connections that loosen over time, butt weld joints create a seamless bond. When welded correctly, the joint eliminates leak points, even when transporting hazardous fluids or gases. This is a game-changer for chemical processing, where even small leaks can contaminate workspaces or harm personnel.

Durable Carbon Steel Construction

Carbon steel is naturally robust, and these fittings are made from high-grade variants that resist wear, impact, and thermal cycling. They can handle temperature changes (from freezing to high heat) without cracking, and they stand up to physical damage from equipment or heavy use. This durability means fewer replacements and lower long-term costs.

Versatile Corrosion Resistance

While carbon steel isn’t as corrosion-resistant as stainless steel, these fittings are designed to withstand exposure to moisture, industrial chemicals, and outdoor elements. They perform well in both indoor (e.g., factory lines) and outdoor (e.g., oil pipelines) settings, making them a flexible choice for diverse industries.

Typical Uses of Schedule 80 Butt Weld Carbon Steel Pipe Fittings

Oil and Gas Industry

In refineries and offshore drilling platforms, Schedule 80 Butt Weld Carbon Steel Pipe Fittings connect pipes that transport crude oil, natural gas, and refined fuels. The butt weld joints prevent leaks in high-pressure offshore environments, while the Schedule 80 thickness resists damage from rough seas or equipment.

Chemical Processing Plants

Chemical facilities use these fittings to move corrosive or toxic fluids. The carbon steel construction resists chemical degradation, and the permanent butt weld connections ensure no leaks that could cause accidents. They’re commonly used in acid transfer lines, solvent systems, and waste treatment pipes.

Power Generation Facilities

Coal, gas, and nuclear power plants rely on these fittings for steam and coolant systems. The fittings handle the high temperatures and pressures of steam lines, ensuring turbines and generators operate reliably. They’re also used in cooling water loops, where durability against constant flow is key.

Heavy-Duty Manufacturing

Steel mills, automotive plants, and mining operations use these fittings for general piping needs. They connect pipes that transport water, air, lubricants, and industrial waste, standing up to the constant use and harsh conditions of manufacturing floors.

Design Specifications of Schedule 80 Butt Weld Carbon Steel Pipe Fittings

Thickness and Material

Schedule: 80 (wall thickness meets ASME B36.10 standards for high-pressure performance)

Material: High-grade carbon steel (selected for strength, weldability, and durability)

Connection Details

Connection Type: Butt Weld (requires welding to fuse with pipes; creates a seamless joint)

Joint Standards: Complies with ASME B16.9 (factory-made wrought butt weld fittings) for consistency

Compatibility

Works with standard carbon steel pipes (diameters range from ½ inch to 24 inches, depending on fitting size)

Suitable for liquids, gases, and slurries (excluding highly corrosive acids that require stainless steel)

FAQ

What welding process is used for these fittings?

Most installers use shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW) for butt weld joints. Certified welders are recommended to ensure the joint meets industry standards, especially in high-pressure systems.

Can they be used in low-pressure systems?

Technically yes, but they’re overkill for low-pressure applications. Lighter schedules (like Schedule 40) are more cost-effective for non-critical low-pressure piping (e.g., residential water lines).

Do the fittings need post-welding treatment?

Yes. After welding, butt weld joints should be cleaned to remove slag. In corrosive environments, the welded area may be coated with a corrosion-resistant material to match the fitting’s durability.

Are they compatible with stainless steel pipes?

It’s not recommended. Carbon steel and stainless steel have different thermal expansion rates, which can cause stress cracks in the joint over time. Use stainless steel butt weld fittings for stainless steel pipes instead.

What quality standards do these fittings meet?

They typically comply with ASME B16.9 (fitting dimensions) and ANSI/ASME B36.10 (carbon steel pipe standards), ensuring consistency across manufacturers and compatibility with global industrial systems.