Industrial piping systems are the backbone of many sectors, ranging from manufacturing and petrochemical to water treatment and power generation. The structural integrity of these systems is crucial for ensuring safety, efficiency, and longevity. As such, selecting the right piping materials and connection methods is paramount. One innovative solution gaining widespread recognition in industrial applications is the cut groove pipe. This article explores how cut groove pipes contribute to enhancing the structural integrity of industrial piping systems, offering significant advantages in mechanical strength, compatibility with heavy-duty materials, simplified maintenance, and cost-efficiency.

1. What Is a Cut Groove Pipe?

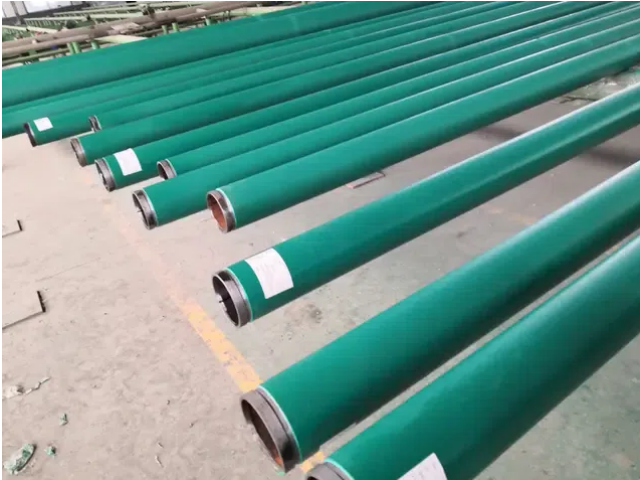

A cut groove pipe is a type of pipe with a precisely machined groove that allows for the use of grooved couplings, which securely join the pipes. This connection method provides a flexible, reliable, and efficient alternative to traditional methods such as welding and threading.

Definition and Basic Characteristics

Cut groove pipes are designed with a groove that is machined into the pipe's end. This groove is then used to engage with a coupling that tightly seals the connection, ensuring a secure and stable joint. The primary characteristic of these pipes is their ability to create a mechanical connection without the need for welding or threading, which are often time-consuming and complex processes.

Comparison with Traditional Connection Methods

In traditional piping systems, welding and threading are common methods used to join pipes. While welding provides a strong, permanent connection, it requires skilled labor, specialized equipment, and can introduce stress concentrations at the welded joints, potentially weakening the pipe. Threaded connections, while easier to install, may not provide the same level of durability, especially under high-pressure conditions.

In contrast, cut groove pipes offer several advantages over these traditional methods. The grooved connection is quicker to install, requires less labor, and can be easily disassembled and reassembled. Furthermore, cut groove pipes are designed to handle a broader range of conditions, including high pressures and temperatures, which makes them ideal for demanding industrial applications.

2. Mechanical Strength Benefits

Cut groove pipes significantly enhance the mechanical strength of industrial piping systems, especially in high-stress environments.

How Groove Connections Reduce Pipe Stress

The groove connection in cut groove pipes helps to distribute the stresses and forces exerted on the pipe more evenly. This reduces the likelihood of stress concentration, a common issue with welded or threaded joints, where the welded areas can become weak points. By reducing stress concentrations, cut groove connections help to enhance the overall strength and durability of the piping system.

Better Vibration Resistance and Load Bearing

Another benefit of the grooved connection is its ability to absorb vibrations. In industrial environments, pipes are often subjected to vibrations from pumps, machinery, and other equipment. Traditional welded joints can crack or weaken over time due to the repetitive stresses caused by these vibrations. Cut groove connections, however, are more flexible, enabling them to withstand vibrations and dynamic loads more effectively.

Long-Term Durability in High-Pressure Applications

Cut groove pipes excel in high-pressure applications due to their robust design and the nature of their connections. The grooved coupling is able to withstand pressure fluctuations without compromising the integrity of the system. This makes them an ideal choice for industries where high-pressure fluid or gas transportation is required, such as oil and gas, chemical processing, and power plants.

3. Compatibility with Heavy-Duty Materials

Cut groove pipes are highly compatible with a wide variety of materials, making them versatile for use in various industrial applications.

Use with Stainless Steel, Ductile Iron, and Carbon Steel

Cut groove pipes can be used with multiple materials, including stainless steel, ductile iron, and carbon steel. These materials are often chosen for their strength, corrosion resistance, and ability to withstand extreme conditions. The grooved connection method is designed to work seamlessly with these materials, ensuring strong, reliable joints without the need for additional reinforcement.

Performance Under Extreme Temperature and Pressure Conditions

One of the key features of cut groove pipes is their ability to perform well under extreme temperature and pressure conditions. Whether in high-temperature steam systems or cryogenic applications, the grooved connection maintains its integrity. This is particularly beneficial in industries that deal with fluctuating temperatures, as traditional connections may fail or weaken over time due to thermal expansion and contraction.

4. Simplified Maintenance and Inspection

In addition to the structural benefits, cut groove pipes offer significant advantages when it comes to maintenance and inspection.

Easier Disassembly and Reassembly

One of the major advantages of cut groove pipes is the ease with which they can be disassembled and reassembled. Unlike welded or threaded connections, which may require cutting or re-welding to make repairs, grooved connections can be quickly and easily disconnected. This feature significantly reduces downtime during maintenance, as workers do not need to spend time cutting or re-welding pipes.

Reduced Downtime and Inspection Costs

The simplicity of disassembling and reassembling cut groove connections also helps reduce inspection costs. Piping systems often require regular inspection and maintenance to ensure they remain in optimal condition. With traditional welded or threaded connections, inspecting the joints can be time-consuming and costly, as it may involve cutting open parts of the pipe. With cut groove pipes, inspectors can easily access the joints and assess their condition, leading to faster inspections and lower overall maintenance costs.

5. Cost-Efficiency in Structural Projects

Cut groove pipes offer several financial advantages, making them an attractive choice for large-scale industrial projects.

Lower Installation Labor Costs

The installation of cut groove pipes is faster and less labor-intensive than traditional methods like welding or threading. As a result, labor costs are significantly reduced, contributing to overall project cost savings. The grooved connection system eliminates the need for expensive welding equipment and specialized labor, making it a more cost-effective solution for many industrial applications.

Reduced Need for Reinforcement Components

In many cases, cut groove pipes require fewer reinforcement components compared to traditional welded systems. This is because the grooved connections are inherently stronger and more flexible, reducing the need for additional support structures. This can result in considerable savings, particularly in large-scale piping systems where reinforcement components can represent a significant portion of the total cost.

Conclusion

Cut groove pipes are a valuable solution for enhancing the structural integrity of industrial piping systems. Their superior mechanical strength, compatibility with heavy-duty materials, ease of maintenance, and cost-efficiency make them an ideal choice for industries where reliability and performance are critical. As industries continue to face the challenges of operating in demanding environments, the adoption of cut groove pipes can help improve system durability, reduce costs, and ensure long-term operational success.

At Weiheng, we are committed to providing high-quality products and services to meet the needs of our customers. Since our establishment in 2011, we have built long-term partnerships with trusted supply chain partners to ensure the best quality and reliability of our products. If you're looking to enhance the structural integrity of your industrial piping systems, cut groove pipes are a smart and reliable choice.

Contact Us

For more information or to discuss how our cut groove pipes can benefit your industrial projects, please feel free to contact us today. Our team is here to assist you with your specific needs and provide the best solutions for your business.