Our Carbon Steel Elbow delivers a perfect combination of strength, precision, and longevity. Produced from high-quality seamless and welded pipes, this elbow offers exceptional resistance to corrosion, deformation, and wear. The long radius elbows (r=1.5d) optimize flow efficiency, minimizing turbulence and pressure loss, while short radius elbows (r=d) provide compact solutions for space-limited installations.

We offer extensive material options to cater to diverse industrial requirements:

Carbon Steel: ASTM A234 WPB, A420 WPL6, 20#, Q235

Stainless Steel: ASTM A403 WP304, WP316L, 321, 1Cr18Ni9Ti

Alloy Steel: ASTM A234 WP11, WP22, WP5, WP91

Surface treatment options include black painting, varnish, anti-rust oil, hot and cold galvanizing for carbon/alloy steel, and polishing or sand-blasting for stainless steel variants. These finishes not only enhance appearance but also prolong service life and reduce maintenance needs.

Our Carbon Steel Elbow is versatile across multiple industries, ensuring smooth fluid transport in pipelines, efficient chemical handling, and structural integrity in high-pressure systems. Each product undergoes rigorous quality testing to meet international standards, offering peace of mind to our B2B clients.

Key Features and Highlights

High Strength & Durability: Withstand high pressure, temperature, and mechanical stress.

Flow Optimization: Long radius options minimize friction and turbulence.

Wide Material Selection: Carbon, stainless, and alloy steel for diverse industrial needs.

Surface Protection: Multiple finishes to resist corrosion and extend operational life.

Compliance with International Standards: ASTM, ANSI, ASME, DIN, JIS ensures reliability.

Versatile Applications: Suitable for petroleum, chemical, power generation, gas pipelines, shipbuilding, and construction projects.

Customizable Sizes & Thickness: Adaptable for seamless and welded pipeline systems.

Specifications Table

Product | DN200 Seamless Elbow A234 WPB |

Size range | 1/2"-24" are made by seamless pipes, above up to 72" are made by welded pipes |

Thickness | SCH20 SCH40 STD SCH60 SCHXS SCH80 SCH160 SCHXXS etc are available |

Angle&Radius | 45 degree,r=1.5d (long radius),r=d(short radius) |

Standards | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9,

JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615,

GB 12459-99,EN Standard etc. |

Materials | Stainless steel(ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect) Carbon steel(ASTM A234WPB,,A234WPC,A420WPL6. 20#,Q235,10#,20#,A3, Q235A, 20G,16Mn, ect) Alloy steel(ASTM A234 WP12,WP11,WP22,WP5,WP9,WP91,16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910,15CrMo, 12Cr2Mo1, ect) |

Technology | Butt-welding,Seamless |

Connection | But welded, socket welded, threaded |

Surface | stainless steel: Polishing, Sand-blasting carbon steel/alloy steel: Black painting,varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE,etc |

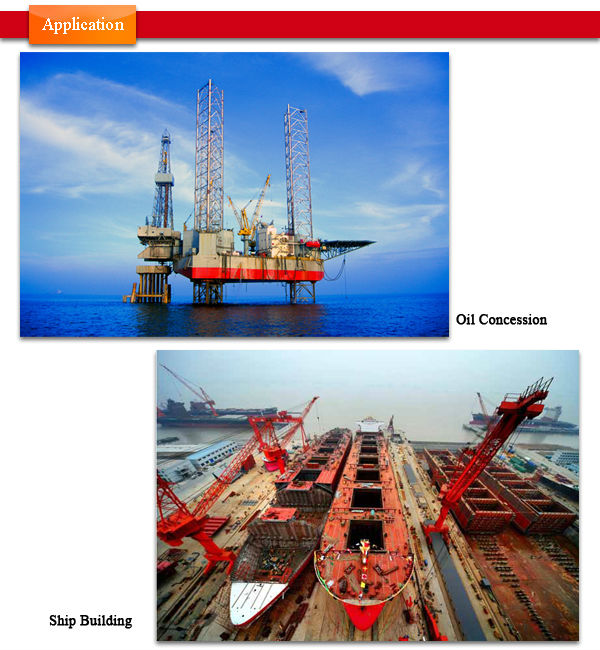

Application | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

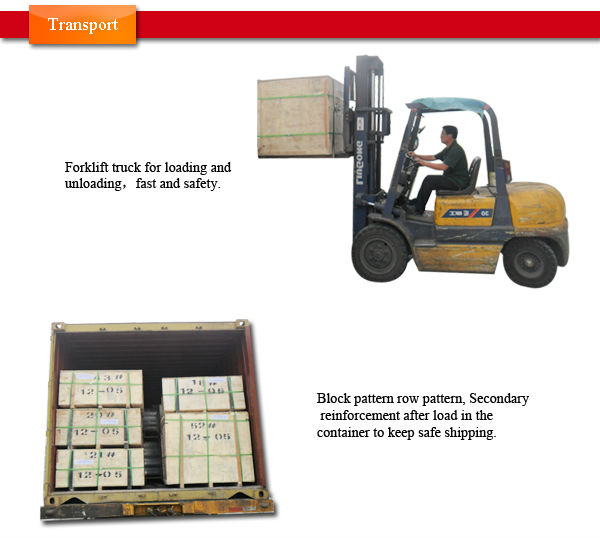

Package | Plastic film, wooden cases ,wooden pallet, or according to customers' request |

Certificate | API, and ISO9001:2000 Certificates,CE,BV, etc. |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality

2.Abundant stock and prompt delivery

3.Rich supply and export experience, sincere service

4. Reliable forwarder |

Port of loading | Xingang (Tianjin) port |

Payment Terms | 30% down payment, the balance 70% T/T before the shipment Or L/C at sight. |

Delivery Time | 7-30 days, according to the order quantity. |

Why Choose Our Carbon Steel Elbow

Competitive Pricing & Superior Quality: Maximize value without compromising reliability.

Extensive Inventory: Ready stock ensures timely delivery for urgent projects.

Proven Supply & Export Experience: Seamless global transactions with secure logistics.

Trusted Partner: Reliable forwarders, secure packaging, and responsive customer service.

Custom Solutions: Flexible sizes, materials, and surface treatments tailored to client needs.

Applications of Carbon Steel Elbow

Petroleum & Gas Pipelines: Secure fluid transport under high-pressure conditions.

Chemical Industry: Corrosion-resistant options for handling hazardous chemicals safely.

Power Plants: Withstand high temperatures and pressures in energy generation systems.

Shipbuilding: Robust construction ensures reliable marine applications.

Metallurgy & Construction: Supports structural integrity and complex piping systems.

By integrating high-quality materials with precise manufacturing, the elbow enhances operational efficiency and longevity, reducing maintenance downtime and improving overall system performance.

FAQs

Q1: What sizes are available for this elbow?

A1: Our elbows range from 1/2" to 24" for seamless pipes and up to 72" for welded pipes.

Q2: Which industry standards do your elbows comply with?

A2: ASTM A234, ASTM A420, ANSI B16.9, ASME B16.9, DIN 2605, JIS B2311, and more.

Q3: Can I choose different materials and surface finishes?

A3: Yes, we offer carbon steel, stainless steel, and alloy steel, with surface treatments like black painting, galvanizing, polishing, and sand-blasting.

Q4: How is the product packaged for shipping?

A4: Options include plastic film, wooden cases, and pallets, customized according to customer requirements.

Q5: What is the typical delivery time?

A5: Depending on order size, delivery ranges from 7 to 30 days.

Story Behind the Product

At our manufacturing facility, every Carbon Steel Elbow represents the intersection of precision engineering and industrial reliability. Designed to reduce pipeline stress and ensure seamless flow, each elbow is a testament to our commitment to quality. By choosing our elbows, clients invest not only in a component but also in the confidence of uninterrupted operations and long-term durability, making their projects safer, more efficient, and cost-effective.