The 180 Degree Carbon Steel Elbow is meticulously engineered to provide seamless connectivity in high-pressure piping systems. Crafted from premium carbon steel or stainless steel, this elbow combines strength, reliability, and precision for industrial and commercial applications. Its smooth surface finish not only ensures leak-free performance but also minimizes friction, providing a clean and safe flow of fluids.

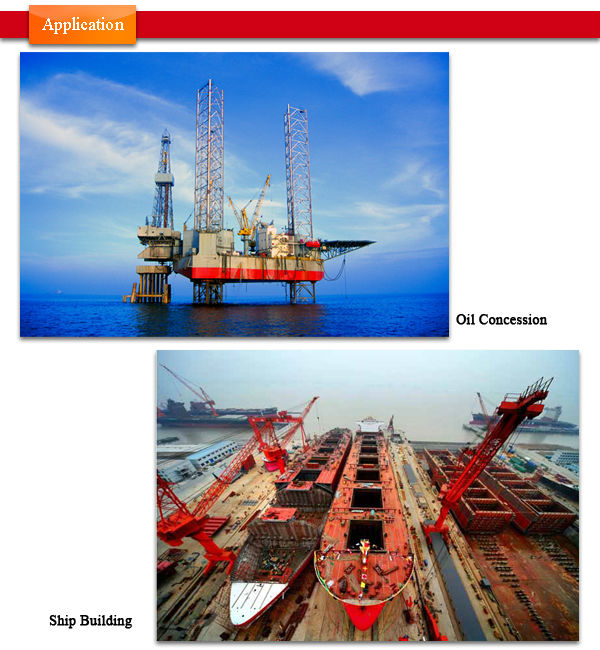

Imagine the peace of mind knowing your pipeline can withstand intense pressures, high temperatures, and corrosive environments without compromising performance. From petrochemical plants to power stations, from water treatment facilities to shipbuilding, this elbow plays a crucial role in enhancing system efficiency while reducing downtime and maintenance costs.

This product is designed with attention to detail. The 180-degree bend allows for complete directional changes in piping without unnecessary space requirements, while maintaining the structural integrity essential for long-term service. Our manufacturing process ensures consistent wall thickness and precise angle tolerances, giving you a flawless installation experience.

Features & Highlights

Premium Material Quality: Made from high-grade carbon steel, with optional stainless steel for enhanced corrosion resistance.

Precision Engineering: Accurate 180° angles with tight tolerance levels, ensuring a perfect fit for all standard piping systems.

Wide Compatibility: Conforms to multiple international standards including ANSI, ASME, DIN, JIS, and BS.

Durability & Strength: Capable of withstanding high pressure and temperature environments, extending the service life of your system.

Smooth Surface Finish: Reduces turbulence, minimizes friction, and prevents scale build-up inside the pipeline.

Versatile Application: Suitable for oil & gas, petrochemical, power generation, water treatment, HVAC, and shipbuilding industries.

Ease of Installation: Seamless or welded configurations available to meet your specific project requirements.

Customizable Options: Various wall thicknesses and size ranges to cater to specialized industrial needs.

Materials & Specifications

Product | DN200 Seamless Elbow A234 WPB |

Size range | 1/2"-24" are made by seamless pipes, above up to 72" are made by welded pipes |

Thickness | SCH20 SCH40 STD SCH60 SCHXS SCH80 SCH160 SCHXXS etc are available |

Angle&Radius | 45 degree,r=1.5d (long radius),r=d(short radius) |

Standards | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9,

JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615,

GB 12459-99,EN Standard etc. |

Materials | Stainless steel(ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, ect) Carbon steel(ASTM A234WPB,,A234WPC,A420WPL6. 20#,Q235,10#,20#,A3, Q235A, 20G,16Mn, ect) Alloy steel(ASTM A234 WP12,WP11,WP22,WP5,WP9,WP91,16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910,15CrMo, 12Cr2Mo1, ect) |

Technology | Butt-welding,Seamless |

Connection | But welded, socket welded, threaded |

Surface | stainless steel: Polishing, Sand-blasting carbon steel/alloy steel: Black painting,varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE,etc |

Application | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

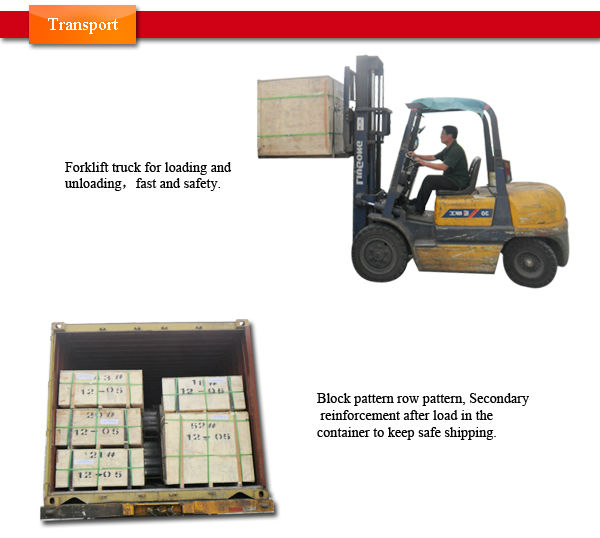

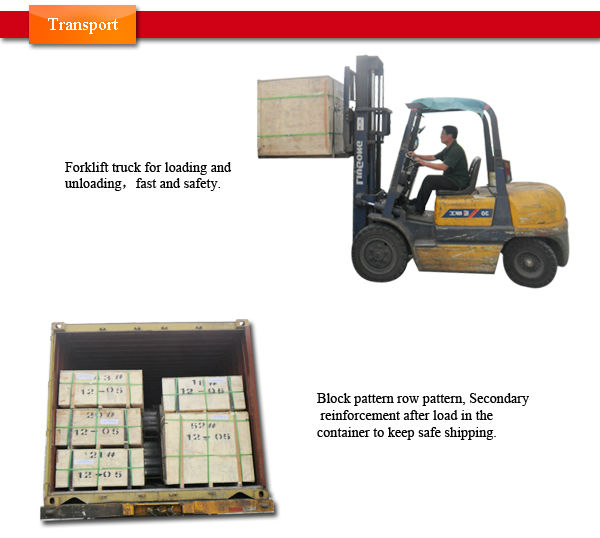

Package | Plastic film, wooden cases ,wooden pallet, or according to customers' request |

Certificate | API, and ISO9001:2000 Certificates,CE,BV, etc. |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality

2.Abundant stock and prompt delivery

3.Rich supply and export experience, sincere service

4. Reliable forwarder |

Port of loading | Xingang (Tianjin) port |

Payment Terms | 30% down payment, the balance 70% T/T before the shipment Or L/C at sight. |

Delivery Time | 7-30 days, according to the order quantity. |

Manufacturing Process

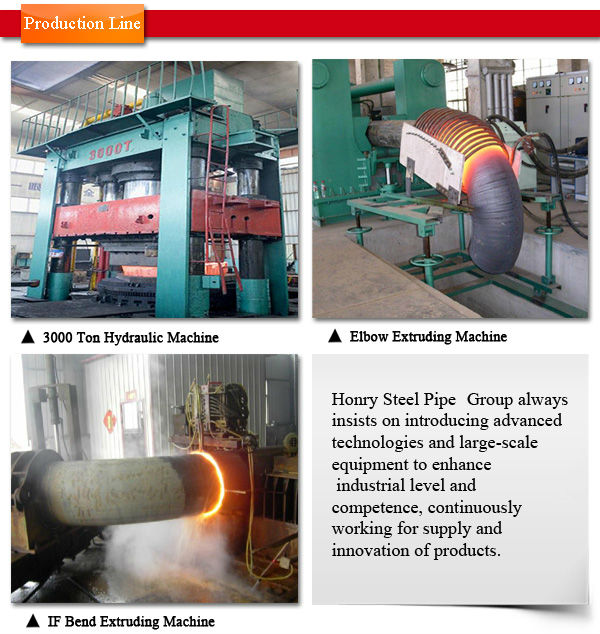

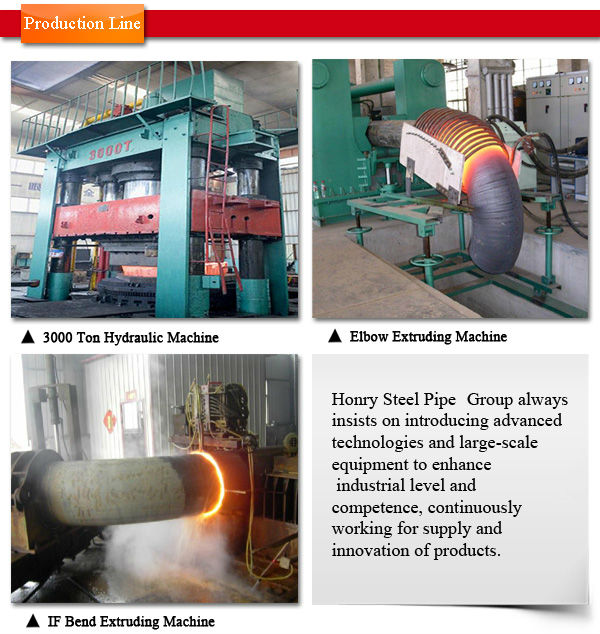

Our 180 Degree Carbon Steel Elbow is produced using state-of-the-art forming techniques to ensure precision and reliability:

Hot Induction Bending: Maintains consistent wall thickness and eliminates cracking or distortion.

Cold Forming: Provides smooth surface finish with superior dimensional accuracy.

Mandrel Method: Ensures uniform internal surface, reducing turbulence and minimizing pressure drop.

Welding Fabrication: Available for larger diameters and customized applications, ensuring structural integrity.

Every elbow undergoes rigorous quality inspection to guarantee performance and reliability in the most demanding conditions.

Quality Control & Testing

Visual Inspection: Ensures smooth surfaces and defect-free finish.

Dimensional Verification: Accurate wall thickness, radius, and angle measurements.

Hydrostatic Pressure Testing: Confirms leak-free performance under extreme pressure.

Non-Destructive Testing (NDT): Includes radiography and ultrasonic testing for critical applications.

Chemical & Mechanical Analysis: Confirms material composition, tensile strength, and hardness meet industry standards.

These steps ensure our elbows deliver consistent quality, safety, and long-term reliability.

Applications

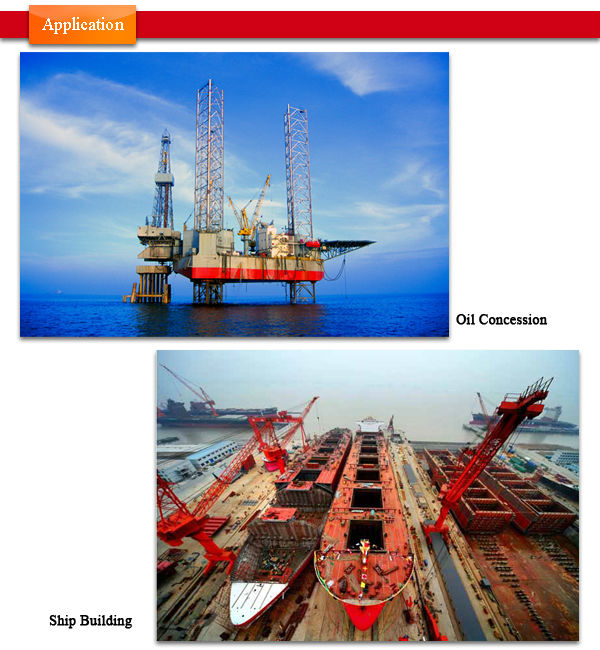

Oil & Gas: Pipelines, refineries, and offshore platforms.

Petrochemical: High-pressure chemical transfer systems.

Power Plants: Steam and water piping systems.

Water Treatment: Clean water and wastewater management systems.

Shipbuilding & Marine: Durable corrosion-resistant pipe connections.

HVAC Systems: Efficient directional flow management in heating and cooling networks.

Mining & Heavy Industry: High-strength piping for slurry and chemical transfer.

Why Choose Us

Expertise & Experience: Over 20 years in precision steel fittings manufacturing.

Global Standards Compliance: All products meet international certifications and rigorous quality standards.

Custom Solutions: Tailored specifications for unique industrial applications.

Reliable Supply Chain: Fast production, on-time delivery, and consistent product availability.

After-Sales Support: Technical guidance, installation assistance, and maintenance advice.

B2B Oriented: Designed to meet the practical needs of industrial buyers, reducing operational risk and improving efficiency.

Frequently Asked Questions

Q1: Can the elbow handle high-pressure applications?

Yes, our 180 Degree Carbon Steel Elbows are suitable for high-pressure pipelines, depending on wall thickness and standard compliance.

Q2: Are custom sizes available?

Absolutely. We provide custom diameters, wall thicknesses, and radius options to match your project requirements.

Q3: What certifications does this product have?

All elbows are ISO9001:2008 certified and conform to ANSI, ASME, DIN, JIS, and BS standards.

Q4: What is the delivery time for bulk orders?

Typically, 20–35 days depending on order quantity and specifications.

Q5: Can you provide welded and seamless options?

Yes, both seamless and welded configurations are available for various industrial applications.